Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Second Co-op Rotation

Dante

Major: Mechanical Engineering

Small-scale production while investing in the improvement and changes in the production process while helping in the applications and quoting areas as well.

SoundOff Signal Winter ý24 Co-op

Jacob

Major: Mechanical Engineering

Documentation, including project requirements documents, certification documents, and DFMEA. Continued to build experience with mechanical design and development validation testing. Worked with external suppliers and dealerships. Introduced to injection molded parts.

Magna Co-op 1st roataion

Daniel

Major: Mechanical Engineering

At Magna, I performed a variety of tasks, these tasks usually included: taking measurements for mirrors and mirror components, building mirror subassemblies, measuring components to ensure everything was within tolerance, and cleaning mirrors. Aside from these more common tasks, I have participated in various small projects like performing gauge R&Rs on various tools we have at the plant, I have also utilized a thermal chamber to see if the mirrors color and bleach at acceptable speeds at extreme temperatures like 50 C or -30 C. I have also operated an Instron machine to perform some tests, like what the pull-off force for the wires is when connected to the solder of mirrors, another test I did was finding what force it takes to have a mirror pop off its mount, and if that force is within its target area.

EGR 390 - 2nd Co-op Rotation - Mechanical Design Intern

Kaylor

Major: Mechanical Engineering

As an intern with little experience in the industry, I mostly do existing drawings based on "as-built" prints whenever possible. However I also have done load calculations for buildings, HVAC piping design, domestic plumbing design, demolition design, and some sheet metal design as well. I have also looked through specifications and cut sheets to calculate which mechanical equipment would be the best performance, as well as efficiency calculations based on utility bills for certain buildings. Every week I find myself doing something new for different projects based on what work needs to be done and who needs help at that time.

Read More About EGR 390 - 2nd Co-op Rotation - Mechanical Design Intern

Manufacturing Engineer Intern

Ryan

Major: Mechanical Engineering

I have made multiple logs which help to monitor shop floor equipment. I created a powder coat recipe book to inform new operators of the proper settings to utilize depending on the parts painted. I have designed and quoted out multiple material transfer carts. I have designed and fabricated new CNC tapping tables. As well as the design, project organization, and fabrication of new window assembly tables.

Genie in a Bottle

Josh

Major: Mechanical Engineering

Through this semester, I was tasked with the responsibility for several work centers and the capital equipment within these work centers used for production.

These work centers included filling, assembly, pick and place applications, automated die punching, packaging, printing, bagging and inspection. Additionally, I was one of the CAD, 3D scanning, CNC programming and fabrication subject matter experts.

SoundOff Signal - Co-op II

Marcus

Major: Mechanical Engineering

Over the semester I was tasked with 60% of my work being focused on a few larger projects, and 40% of my work being non-project work. The larger projects focused on product development, fixing recurring problems found in the field, updating products to match new and upcoming vehicle refreshes, and even working with other companies to develop new and innovative designs for future products. The smaller non-project work was focused on helping out other engineers and supporting them on their projects. I did a bunch of data collection, prototyping and building, running "errands'' to different outsourcing companies, and other supportive tasks. One of my larger projects was designing and building portable display boards for our Fire/EMS lighting. It was an incredible learning experience and I got to learn about our company's products, the design process, working with suppliers, working in a team, and seeing a project all the way through.

Second Rotation at RDI

Sean

Major: Mechanical Engineering

A majority of my time was spent working on CAD files. I also cleaned and stored the casting tools after they were used, and I sent emails and filed paperwork for the engineering department. I also conducted some reverse-engineering on new parts that were transferred to the foundry.

Co-Op rotation 2

Benjamin

Major: Mechanical Engineering

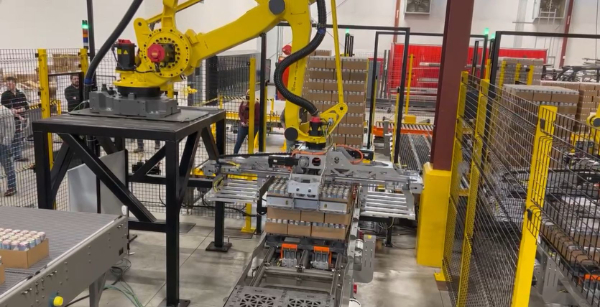

I was asked to program and integrate many different types of equipment such as robots, conveyors, motors, sensors, etc. and program a PLC to allow the machine to function as intended.

Co-op Rotation 3

Grant

Major: Mechanical Engineering

I worked as a floor engineer for all 3 rotations. While assemblers would run into issues assembling facilities on the floor, I would meet with them to discuss and observe the issue firsthand. I would then consult with an appropriate project engineer regarding a potential solution and move forward from there. My job was to repeat this process for any assembly issues throughout the workday.

Tommy Car Wash Systems Product Engineering Co-op

Grant

Major: Mechanical Engineering

For my first two rotations here at Tommy's, I worked in the product engineering department which focuses on updating and creating manufacturing prints for the major assemblies. This semester I worked with the research and development team. I have helped out in many ways but spent the majority of this last rotation working on designing and creating a manufacturing fixture for our water softener system. This will allow for much simple production and less mistakes.

Read More About Tommy Car Wash Systems Product Engineering Co-op

Mechanical Engineering third co-op rotation at Irwin Seating Company

Ben

Major: Mechanical Engineering

Around 90% of my time was dedicated to helping the development of a new recliner. (see attached picture) I did a lot of CAD modeling for this project as well as being involved in the discussion and decisions on various design choices. The other 10% of my time was dedicated to a mix of helping problem solve other upcoming products, miscellaneous tasks, and upkeep of the engineering space.

Read More About Mechanical Engineering third co-op rotation at Irwin Seating Company

Trane Technologies Co-op - Rotation 3

Skyler

Major: Mechanical Engineering

During the third rotation, I was responsible for updating work standard documents for the production floor. I also was responsible for hosting a weekly quality log meeting in efforts to learn from engineering mistakes. Lastly, I worked through an A3 project in efforts to reduce warranty spendings caused by engineering.

Final Co-Op

Trevor

Major: Mechanical Engineering

I worked as a general manufacturing engineer interning. I supported a assembly and a fabrication area. I implemented various improvements to increase ergonomics and the production of the assembly line. I worked on new improved fixtures for products. I also worked on general improvements for the line.

Final Rotation of Co-op at Panduit

Nicholas

Major: Mechanical Engineering

My primary project was to organize a team of engineers and lead meetings to develop a new product. The solution I was involved in will extend Panduit's current offering of cable cleats, which is a product that secures cables in the case of a short circuit event, or disaster. I was mainly involved in the brainstorming and iteration phase of the project, where I created concepts based on feedback and constraints, and assisted in financial estimations and planning for the project. Additionally, I assisted in 3D CAD modeling our other products based on engineering drawings, updated documentation, and managed a full testing and comparison of metal locking cable ties and strapping products.

IPM Co-Op Third Rotation

Kyle

Major: Mechanical Engineering

As a mechanical engineering co-op, I worked with the mechanical engineering department to design conveyor for multiple customers. I have worked with tabletop, mattop, MDR, and pallet conveyor during my time at IPM. Typical project procedure involves receiving the conveyor layout, calculating values to test for any difficulties, create 3D models of the conveyor, compile BOM's for purchasing, and sometimes find vendors to supply parts. Modifying parts and trouble-shooting conveyor once it is built to correct for errors is also part of the experience.

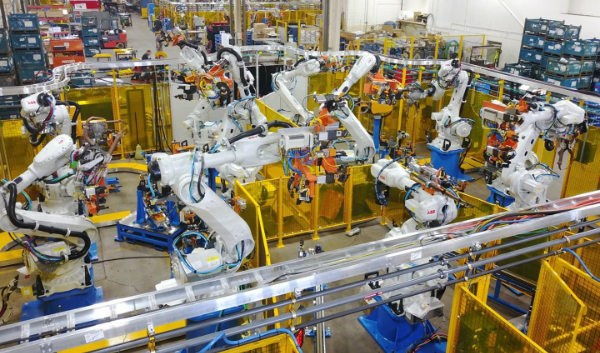

JR Automation Co-Op Experience

Samuel

Major: Mechanical Engineering

During my time as an AE, my main focus during training was learning how to quote an automation project (it always costs far more than what you think it will). Within this field, I also worked on concepting of these projects, as well as virtual simulation of potential designs.

As an ME, my main focus during training was to learn how to refine the initial designs of the AE's in order to make consistent, safe, and reliable piece of automation. Various smaller tasks include, but are not limited to: creating/checking prints/details, product design, machining, etc.

Rubber Engineering

Andrew

Major: Mechanical Engineering

Product design team. Creation of studies related to fatigue, parts testing, prototype assembly

Experience Matters

Anthony

Major: Mechanical Engineering

As an Advanced Manufacturing Engineer my responsibilities included, but were not limited to, process optimization, technology integration, design and development, quality assurance, project management, troubleshooting, collaboration and communication, continuous improvement, compliance and safety, training and documentation.

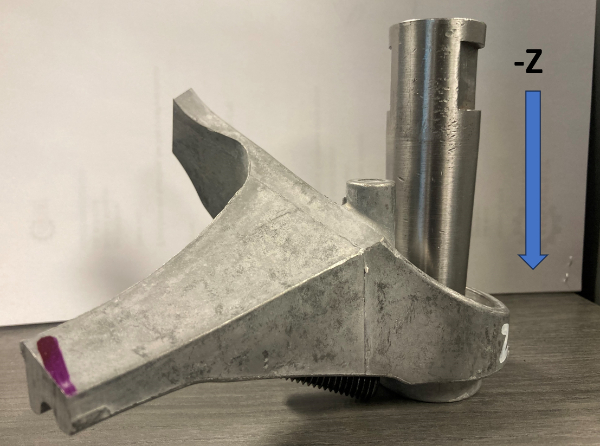

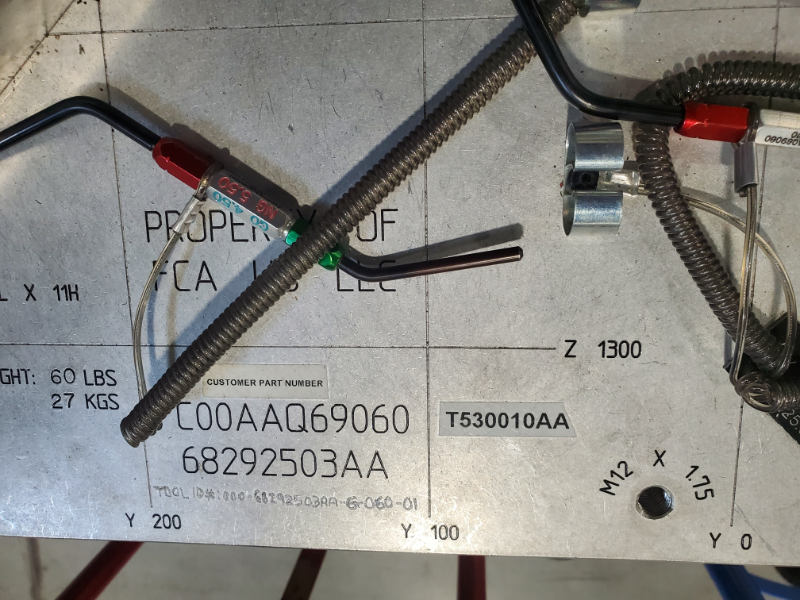

Third Co-op Rotation at Axis Automation

Zachary

Major: Mechanical Engineering

A large amount of my time this semester was spent working on tooling station and robot end effector designs. This includes but is not limited to initial designs, internal and customer design review meetings that require design changes, compiling documentation for the components to be machined and built, and overall job documentation for the customer.

Last CO-OP Rotation

Ali

Major: Mechanical Engineering

As far as projects Iýve worked on, one project was a cabinet sent by a customer where I had to go over the entire drawing package, create flat patterns, build BOMs & routers, add weld symbols if needed, apply GD&T where applicable, and process WOs. That was a project that was assigned to me, and I was responsible of getting everything completed before we can send it out to the floor. Iýve also worked in the assembly department for a couple weeks where I helped assemble

some of the components of that cabinets such as the door, door jams, locks&etc.

3rd Co/op at NN Inc.

Connor

Major: Mechanical Engineering

This semester I had more independence and had control of my own product line. I provided assistance to each process on the line on mostly day-to-day operations. I also had the opportunity to learn a new machining operation which included learning the process flow, maintaining the machines, and increasing production.

Viking Products Incorporated Third CO-OP Rotation

Darwin

Major: Mechanical Engineering

In the third rotation, I was able to have more responsibility in creating and modifying Annual Validations or PPAPs for different parts. Through this, I was able to have thorough understanding of the different levels used to specify what should and should not be in these revalidations. I was also able to learn more about the Instron machine through testing parts for proof loads and tensile strength respectively. Additionally, I was able to sharpen my skills in creating RIR work instruction for different parts as well as maintaining quality of the gauges registered in the company.

Read More About Viking Products Incorporated Third CO-OP Rotation

Co-op 2

Trevor

Major: Mechanical Engineering

I assited in a varity of product launches from ordering tooling, fixtures, and problem solving. Also I supervised an area and assisted in day to day operational issues.

2nd Co-op Rotation

Ethan

Major: Mechanical Engineering

My main task was running laser cell production which included cleaning, repairs, and other general maintenance on the 6 laser cutter machines as well as the Sort Ný Etch. I also completed side projects of 2D CAD and gcoding, 5s projects, cycle time improvements, welding, duct work, motors, etc.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.