Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

In-home Behavior Technician

Major: Psychology During my time at BRAINS as a Behavioral Technician I have worked with 6 different clients 1:1, 5 of those being in home, and 1 being in a school setting. These children are all on the Autism Spectrum and have behaviors that are preventing them from being successful in their everyday lives. The parents of these children work with the Board Certfied Behavior Analysts (BCBAs) that I work under, to develop a list of goals for each child. The BCBA then formulates a plan based upon each individual's unique circumstances, and I, as the behavior technician, carry out this plan. In practice, I meet with each child on my caseload a couple times a week for a few hours at a time, and we will do anything from read to play pretend, all while working on things like functional communication (using your words to get what you need or want), relinquishing of control (not needing everything to go exactly to plan), and peer relationships.

Helping Foster Care Children

Major: Psychology My main task throughout the semester was to scan and organize various forms that were required for each case every 30 days. There were forms for gas mileage, monthly reports, determination of care forms necessary every 6 months, and reimbursement forms for foster families. I also shadowed my supervisor, Lydia, while she worked on referral calls and team meetings to assess a child's progress or placement. Monthly my supervisor would have house visits and I would attend with her. When a case aid was not available, I also helped in transporting kiddos to/from school, to parent visits, or dropped off court reports to the district court. Occassionally, I attended court hearings in reference to my supervisor's caseload, though rarely.

Third Co-op Rotation Experience

Major: Interdisciplinary Engineering During this rotation, I had the opportunity to contribute to several projects at various stages of design, allowing me to develop both technical and project coordination skills. One of the assignments I supported involved the early design phase for a camp facility. For this project, I completed preliminary electrical load calculations and prepared accompanying written narratives outlining the project scope, design considerations, and assumptions. These documents formed the foundation for the projectýs electrical design direction. I also participated in two healthcare-related projects, where our team conducted on-site visits and walkthroughs to document existing conditions. I assisted in gathering photos, measurements, and field notes, which will later be used to inform the redesign of electrical systems within the updated space layouts. In addition, I continued work on a project from my previous rotation: the new Lansing City Hall. My responsibilities included updating portions of the electrical design to accommodate a change order, which involved re-laying out power distribution and adjusting lighting and circuiting plans to meet the revised requirements. Beyond project-specific work, I improved an internal load calculation Excel tool used by the electrical team. I refined the structure and formulas to make preliminary calculations more efficient and user-friendly. To support future users, I also created a detailed instructional write-up that included step-by-step guidance as well as relevant code references needed during the calculation process.

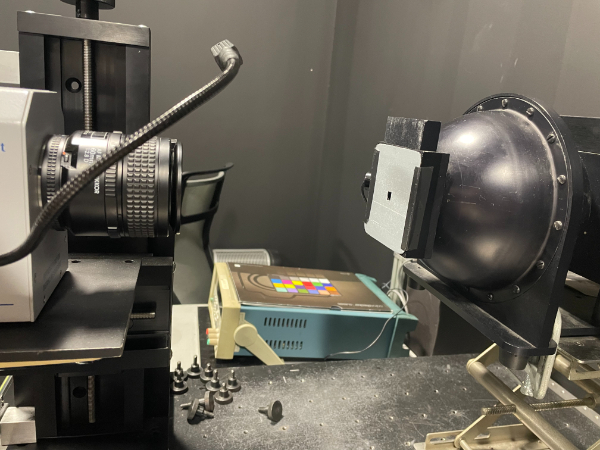

EGR 490 Rotation

Major: Electrical Engineering In my semester at Mission I was exposed to a tremendous amount. I mostly was used as support for lead controls engineers. This involved cleaning up PLC programming, HMI screens, and AutoCAD Electrical Drawings. There were various times where I was required to set up a prototyping demonstration for customers to see. This involved mocking up a simple station that demonstrated that the company(Mission) is capable of preforming what the customer is asking us to do. I have had to use different equipment such as Fanuc Robots, different lighting, different robot end of arm tools, and cameras. I honestly think this gave me a lot of experience. It allowed me to mess around with the equipment. A lot of automation equipment has different software that is required for it to operate, this allowed me to gain knowledge on that side as well. I have prior experience with PLC programming and HMI Design, but Mission allowed me to excel. I was given lots of opportunities to home in on my programming skills.

Third Rotation

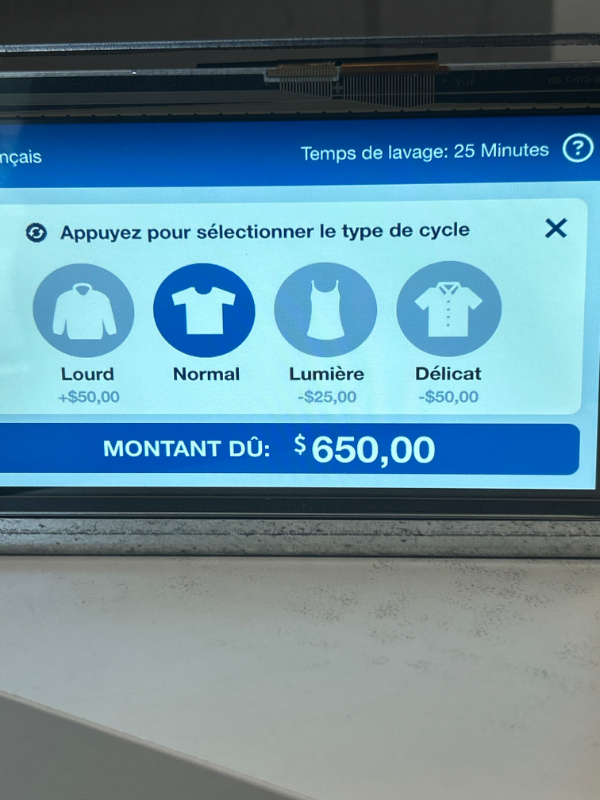

Major: Computer Engineering This rotation I was tasked with maintaining and debugging a complex IoT commercial washer/dryer software. This included a complex state machine which controlled motors and relays and wayer valves for the carious washers.

EGR 490 Co-op Rotation III

Major: Biomedical Engineering I ran cycle time studies for two different production lines, inside and outside of a cleanroom. I had also created and/or edited various documents, such as work instructions, production routers, and visual defect libraries, to make them easier to read and provide better explanations for steps. I had also developed process flow diagrams for two production lines to show the steps for making each finished good from materials coming in to shipping to the customer. Lastly, I have ordered spare parts for multiple production lines using an ERP system to place requisitions and contacted suppliers to fulfill the orders.

Co-op Work Experience

Major: Product Design and Manufacturing Engineering During my third co-op rotation at Trans-Matic, I had the opportunity to independently design and plan a completely new job. In a previous rotation, I worked closely with my supervisor to develop a new job design and layout. This time, I was able to take on a lead role with significantly less supervision. My responsibilities included scheduling and leading project meetings, maintaining thorough documentation, and completing key milestones throughout the tool design process.

Third Co-op Rotation as an Engineering Intern at Viking Products, Inc.

Major: Biomedical Engineering As a third rotation co-op engineering intern, I helped a lot with prototyping and aided in preparing parts for production. This involved physical testing and dimensioning of the parts to analyze the performance of the parts in their initial phases, part inspections, standard documentation, and working with overseas suppliers in charge of the manufacturing of the parts to assure the processing of the parts. I wrote work instructions, put together PPAPs, and worked heavily with CAD drawings and modeling. I also worked with customer quotes, making preliminary drawings and performing drawing comparisons to analyze customer requirement specifics and part revisions. As interns, we also work with shipping, pick up and deliver parts, and help the warehouse team with inspection and sorting of parts as they come in and get prepared for shipping.

Read More About Third Co-op Rotation as an Engineering Intern at Viking Products, Inc.

Low Voltage Distribution Planning

Major: Electrical Engineering Assist engineers in planning and maintaining the electrical distribution system. Addressed repetitive outage problems, system upgrades, and general maintenance.

Final Engineering Co-op Experience

Major: Mechanical Engineering This rotation I spent each 5 of the 15 weeks in different departments. First, I was in project management where I learned how to effectively communicate with customers and about different processes. The second rotation I was in was process engineering where I got to see more of the electrical side of things. Finally, I got to spend time in tool design learning about different tools in some of our machines and how the program the team used works.

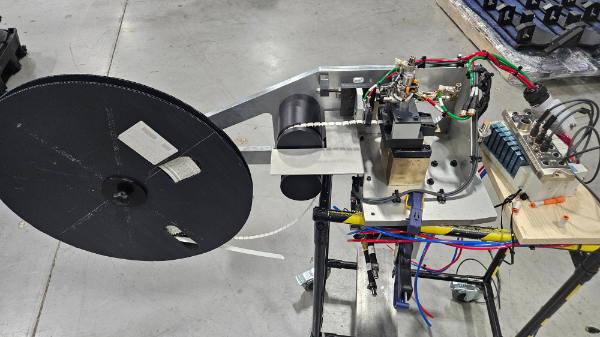

Controls Engineering Coop

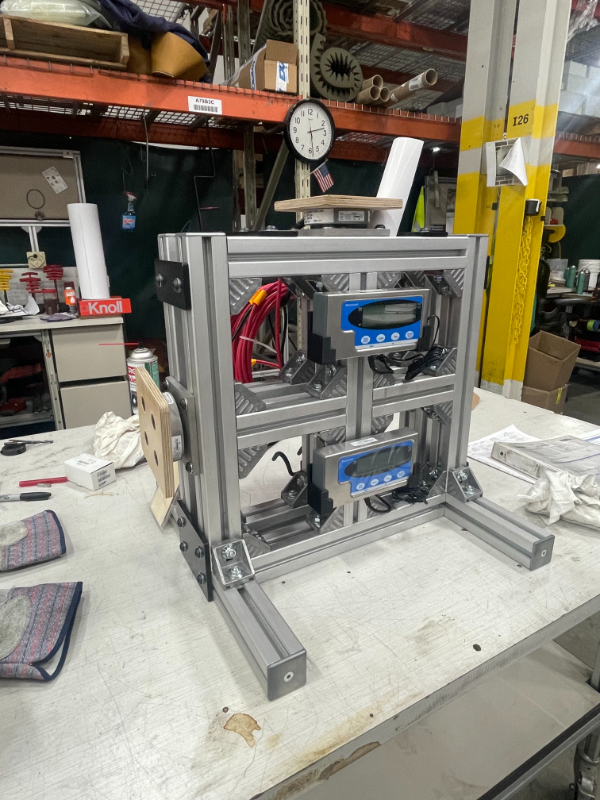

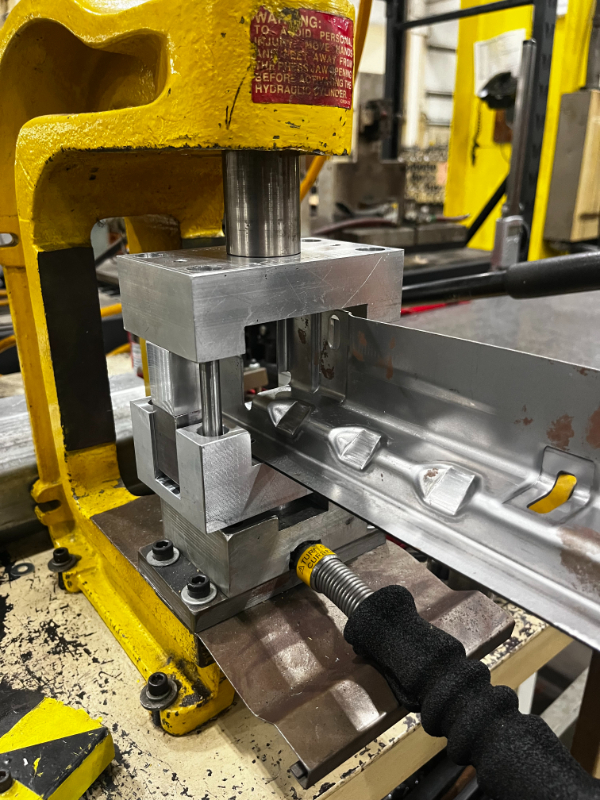

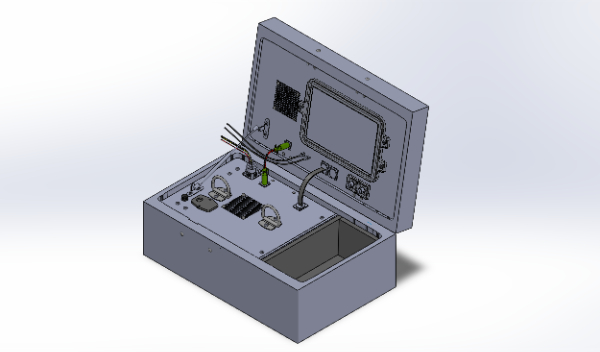

Major: Electrical Engineering Over the past three semesters, I have contributed to a wide range of projects that have strengthened both my technical and practical skills. These have included numerous smaller R&D initiatives to validate concepts before integrating them into production equipment, as well as updating electrical schematics with redlines to correct wiring issues and improve documentation accuracy. I have also set up and operated a 3D profiling system to scan customer parts and generate the required measurement data. Most recently, I developed a control program from scratch for a punch cart, using four pneumatic cylinders to grip, move, secure, and punch customer parts. In addition, I have supported Mission engineers on customer sites during machine installations, gaining valuable hands-on experience and building strong customer-facing skills in real-world environments.

F25 Third Co-Op Rotation

Major: Mechanical Engineering During my third rotation at HermanMiller, I've been given greater responsibility when designing fixtures and assemblies when compared to previous semesters. Often I was given a project, where then I was responsible for contacting the customer, conducting design reviews, and giving oversight to the machine builders after the design is released for assembly.

Magna Mirrors Co-op as an OSM Intern

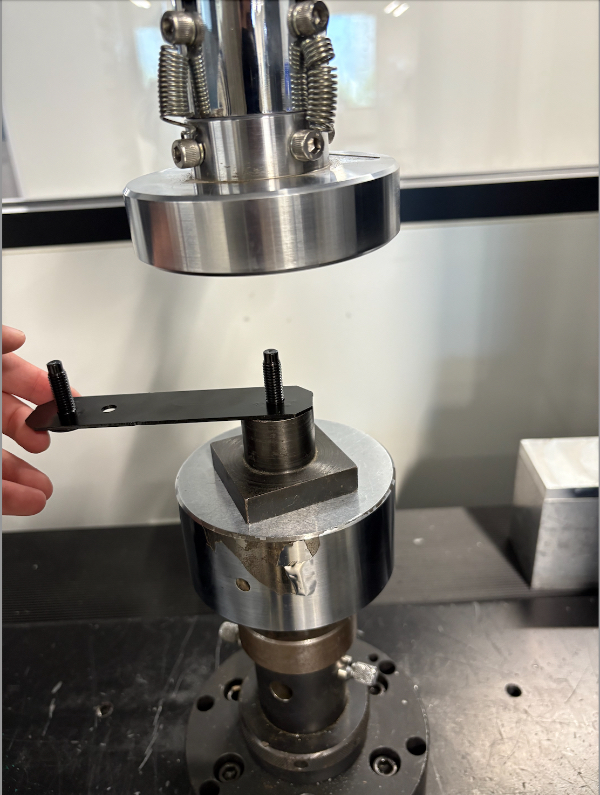

Major: Mechanical Engineering As I worked for Magna mirrors the tasks, I was given had such variety throughout the semester. Some of these tasks include various methods of testing using the Instron to measure force or tension. Measuring the vibrational frequency of how the mirrors behave on the road in certain conditions. As well as even being given a specific project to create a fixture attachment to verify how many cycles some mirrors have completed in a chamber.

Co-Op 3 Magna Mirrors

Major: Mechanical Engineering During my 3rd co-op rotation, I supported multiple engineering activities within the product development and manufacturing processes. My work included assisting in design validation testing, documenting test results, and troubleshooting mechanical and electrical issues on mirror and vision-system components. I created and updated CAD models and engineering drawings, supported build events, and helped implement design changes based on testing and customer requirements. I also assisted with root-cause investigations for component failures, contributed to fixture improvements, and coordinated with cross-functional teams, quality, manufacturing, and program management to ensure issues were resolved quickly. Additionally, I took on data collection and analysis tasks, organized test/inspection documentation, and maintained clear communication with senior engineers to keep project timelines on track.

My Final Co-Op Rotation

Major: Biomedical Engineering I have completed many tasks this semester. These tasks include CAD projects where I have designed a CMM mount for a gear rack which is a part produced here, a pre-assembly fixture poka-yoke, a trunnion gauge block, a rivet funnel, and a rivet pullout force fixture. These are all made or in the process of being made by toolroom to be used on the plant floor. I have also performed capability studies on multiple new parts to include them in the PPAP packages. I also made a color chart for die CAD and organized all of the company PPAP packages by moving them into the PLEX software. There are various other tasks I have completed but they are a much smaller scale, such as work instructions or inventory.

School-based Mental Health Internship

Major: Psychology I administered activities that help students (grades K-6) with executive functioning, emotional regulation, and mindfulness skills. I administered/took notes for threat assessments Provided a safe space for students who were struggling and needed to discuss how they were feeling. Being a member within IEP meetings.

Fixture Design & Product Testing Co-op Review ý Navico/Lowrance & Lenco Systems

Major: Mechanical Engineering During this co-op rotation, my primary responsibilities centered around hands-on engineering support within the test lab. I designed and built multiple test fixtures for new product development and product verification testing, including large welded steel assemblies and custom machining work. I also completed repairs and upgrades to existing fixtures to extend their usability and improve testing efficiency. In addition to fixture work, I contributed to improving and updating shop equipment and machinery, including tuning and upgrading the large-format 3D printer and performing general shop optimization tasks to support daily testing operations.

Read More About Fixture Design & Product Testing Co-op Review ý Navico/Lowrance & Lenco Systems

MAGNA Mirrors 3rd Rotation

Major: Product Design and Manufacturing Engineering The main project I worked on this semester was creating a design and a Bill of Materials for a new suitcase tester for mirror programs that are being rewarded to MAGNA. This involved working with the Project Managers and Project Engineers at the Holland Location as well as consulting the Electrical Engineers at the 36th St location. I also tested a new chemical composition in mirrors that would allow our facility to save around $40,000 if testing is giving adequate results.

Autocam Medical Third Engineering Co-op Fall 2025

Major: Product Design and Manufacturing Engineering This rotation I continued to provide engineering support at the manufacturing cell I am a part of, which specializes in laser marking the surgical equipment after the primary operations (that machine the main geometry of the part), and enter the secondary operations. The value streams converge at the manufacturing cell I get to be involved at, and I get to have hands on experience with High Mix and High Volume components. The main project I developed this rotation was a discrete event simulation (DES) using JaamSim to simulate the production output of my manufacturing cell with data collected with the product data management system and the PLC's in the machines. This allowed for the necessary data to be fed into the simulation that I made, and compared with real life data for validation. This simulation is the first one that has ever been made by a co-op student, and I was able to successfully develop a simulation that can accurately reflect the behavior in the manufacturing floor and simulate "what if" scenarios.

Read More About Autocam Medical Third Engineering Co-op Fall 2025

3rd Rotation Co-op

Major: Product Design and Manufacturing Engineering This semester I've been helping with the qualification and calibration of fixtures used in a new process, PTFE etching. I've also been helping to manufacture the PTFE tubes through blow molding, laser cutting, and tipping.

Bringing Mobility Forward for All

Major: Product Design and Manufacturing Engineering During my time at Magna, I've had the hands-on opportunity to characterize and build mirrors products. I have also been given the opportunity to work directly with multiple leaders of various groups within the organization. I've conducted experiments in both lab and manufacturing floor settings, developed internal product specifications, and benchmarked various products to support my team in bringing mobility forward for all.

Co-op Rotation Semester 1

Major: Mechanical Engineering Some of the tasks I completed during my first co-op rotation were updating various designs of wash arches and components, updating prints by taking feedback from the production and service teams about pain points that need to be addressed. A larger project I took on was to update and redesign our in house built pressure washer that we provide should our customers need it.

Viant Medical Co-op Rotation 1

Major: Biomedical Engineering During my time on the line, I completed a variety of tasks and projects that ranged from technical documentation to hands-on fixture development. I improved existing work instructions for several stations to enhance clarity and usability for operators, and I created new documentation to support the integration of equipment into the line. These efforts ensured that both legacy and new processes were clearly communicated and easy to follow. I also authored engineering build reports to verify that components from new suppliers met customer specifications and functioned properly within the final product. On the hands-on side, I designed and 3D-printed a fixture to hold five work-in-progress pieces, improving workflow and organization at the station. Additionally, I evaluated other fixtures and prepared them for production, ensuring they were ready for deployment and met operational standards. These projects reflect a balance of technical writing, process improvement, and practical engineering support.

Co-Op at Met-L-Flo

Major: Mechanical Engineering During my first semester of co-op at Met-L-Flo, I spent a significant amount of time on the production floor, gaining an understanding of the processes the company uses to manufacture parts. During my time on the production floor, I learned everything to do with casting. This included making the molds, cutting open the molds, casting the parts, finishing the cast parts, and finally shipping the parts out. In addition to working on the production floor, I also did some design work for both outside the company and internally. This was quite a challenge as the designs were left almost completely up to me with only a small amount of guidance. I think this challenge was good.

Economic Recovery Specialist

Major: Political Science I used computer programs like Karpel, and TLO Search, receive and receipt diversion fee and merchant fee payments, prepare default judgments, made trial binders, watched bodycam footage and made notes, reviewed evidence and note if there is anything important that someone may have missed.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.