Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

EGR 490 Rotation

Logan

Major: Electrical Engineering

In my semester at Mission I was exposed to a tremendous amount. I mostly was used as support for lead controls engineers. This involved cleaning up PLC programming, HMI screens, and AutoCAD Electrical Drawings. There were various times where I was required to set up a prototyping demonstration for customers to see. This involved mocking up a simple station that demonstrated that the company(Mission) is capable of preforming what the customer is asking us to do. I have had to use different equipment such as Fanuc Robots, different lighting, different robot end of arm tools, and cameras. I honestly think this gave me a lot of experience. It allowed me to mess around with the equipment. A lot of automation equipment has different software that is required for it to operate, this allowed me to gain knowledge on that side as well. I have prior experience with PLC programming and HMI Design, but Mission allowed me to excel. I was given lots of opportunities to home in on my programming skills.

Low Voltage Distribution Planning

Sam

Major: Electrical Engineering

Assist engineers in planning and maintaining the electrical distribution system. Addressed repetitive outage problems, system upgrades, and general maintenance.

Controls Engineering Coop

Mitchell

Major: Electrical Engineering

Over the past three semesters, I have contributed to a wide range of projects that have strengthened both my technical and practical skills. These have included numerous smaller R&D initiatives to validate concepts before integrating them into production equipment, as well as updating electrical schematics with redlines to correct wiring issues and improve documentation accuracy. I have also set up and operated a 3D profiling system to scan customer parts and generate the required measurement data.

Most recently, I developed a control program from scratch for a punch cart, using four pneumatic cylinders to grip, move, secure, and punch customer parts. In addition, I have supported Mission engineers on customer sites during machine installations, gaining valuable hands-on experience and building strong customer-facing skills in real-world environments.

Controls Engineer Intern

Andres

Major: Electrical Engineering

During my rotation, I worked on different projects, for example, MES, which is the system for the downtimes of all the machines across the production floor, making new windows in ignition software, and helping reduce the number of software used across the plant to only use Ignition.

The First Steps of my Career: Finding Passions and Opportunities

Jorge

Major: Electrical Engineering

As I was new to joining the company, got had task to help ease me into the position. For instance, one of my team members was generous to lend us a copy of a drawing he was working on in Maestro, which I was tasked to wire and place control components on the drawing. Furthermore, my team showed me a calculator on excel that I was tasked create wire systems that didn't exceed specific voltage levels on the excel sheet.

Read More About The First Steps of my Career: Finding Passions and Opportunities

First co-op rotation at Miller Knoll as an EE

Doug

Major: Electrical Engineering

Trouble shooting PLC alarms to reduce consistency, implementing and and modifying parts of machines to facilitate work flow, and using NFCs/RFIDs to organize PLC and other electrical components.

Read More About First co-op rotation at Miller Knoll as an EE

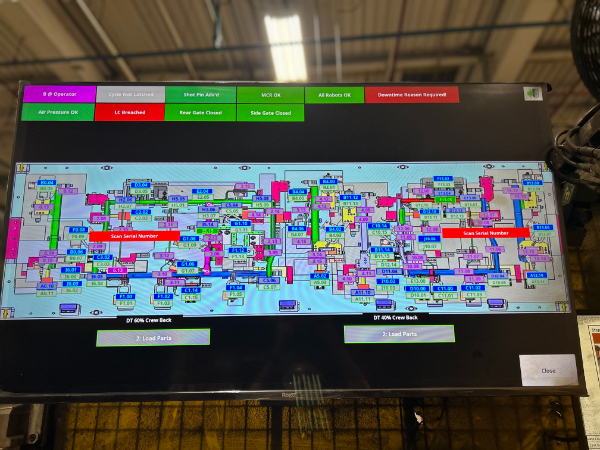

Adient Controls Engineering Co-Op

Zachary

Major: Electrical Engineering

I worked on and completed a variety of tasks throughout the semester. This included updating/writing PLC logic, updating/making HMI screens, updating/making Ignition screens, and helping fix any problem that arose. This could be helping sort non-conforming parts, troubleshooting machines, or helping out other departments. I had my projects to work on, but constantly got pulled off to help with the next hot project, which kept my work days interesting.

Ready for Launch

Ian

Major: Electrical Engineering

This rotation I had the incredible opportunity to work on a microsatellite for a company called Spacecoin, this satellite will be launching in late December and is the first launch in the plans for a whole constellation.

Semester 2 in CAS

Izik

Major: Electrical Engineering

Some key items I worked on this semester included: adding additional capability to testing equipment, developing cables, developing test station code, managing test equipment, ordering equipment, documentation and sustaining duties.

3rd Co-op Rotation

Freddy

Major: Electrical Engineering

I have worked mostly on Outside Mirror products in my three co-op rotations. In this last one, I worked on debugging PCB boards using oscilloscopes, spectrum analyzers and DMMs for some projects that are currently being developed. I was part of the testing process in which involves learning customer's specifications and concepts such as EMC and best design practices on the automotive industry. With the Outside Mirror product line, it involves a good amount of building harnesses, making prototype boards and helping the Validation group with any test that needs to be done.

Co-op at Phase 1

Isabelle

Major: Electrical Engineering

At Phase 1, I completely tasks such as surface mount soldering, EMC emissions scan, GPS sensitivity testing, PCB design, circuit design, data analysis, and RF design.

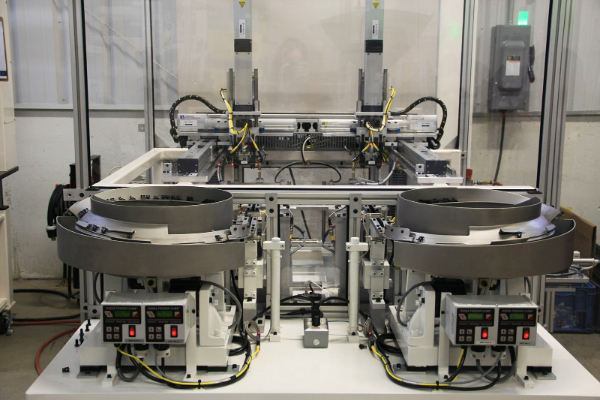

Controls Programming at Koops Automation

Charles

Major: Electrical Engineering

All tasks surrounded programming Programable Logic Controllers (PLC). My entire time at Koops, the work I did was in direct support of an ongoing project. I was doing real work.

First Semester at SoundOff Signal

Grant

Major: Electrical Engineering

Much of my role as a starting EE intern revolved around learning the company's process and

products and assisting with tasks to alleviate some of the more time-intensive work from the

product development teams. This involved assembling various prototype PCBs and harnesses,

establishing and executing thermal tests to compare products with that of competitors,

managing the electronics lab and its contents, and many other tasks to assist the EE team and

Product Development team as a whole.

Viastore Co-Op 1st Rotation

Noah

Major: Electrical Engineering

While working with Viastore I worked on two separate projects for GM. This consisted of commissioning various parts of an Automated Storage and Retrieval System (ASRS). This involved debugging PLC code as well as installing I/O devices, connecting them via ethernet, ensuring communication, and setting conveyors speeds to meet customer specifications.

EGR 290

Logan

Major: Electrical Engineering

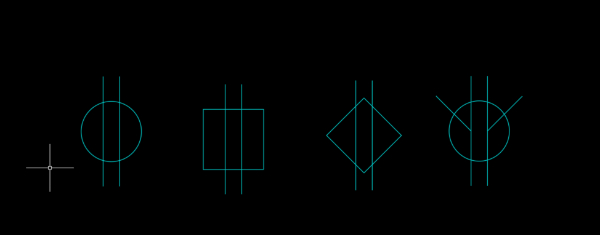

As a co-op of the power systems group on Corteva's Midland site, I was able to learn the engineering behind powering a extremly large chemical site. The largest project I was taked with was updating meter and relay devices for 20 different feeder circuits in two of our switching stations. This invovled updating/creating 120 different electrical drawings, specifically three-line, DC diagram, and connection diagram. In addition, I used a simulation software called ETAP to simulate faults on different parts of each circuit. This allowed us to theorectical see what would happen if a fault occured on one the ciruits, and how to relay would protect the equipment potentially impacted by the fault. I was also able to order parts for this porject, create procedures to turn specific sections of the bus off. I was also, fortunate enough to manage the implementation of one of the circuits I worked on. Unfortunately, in a chemical plant my group isn't allowed to just go turning off chemical processes when we want. It could be months to years before the other circuits I worked on could be implemented. I had other smaller projects that involved other smaller updates to electrical drawings, I was also able to experience some work with PLCs.

Phase 1 is number One

john

Major: Electrical Engineering

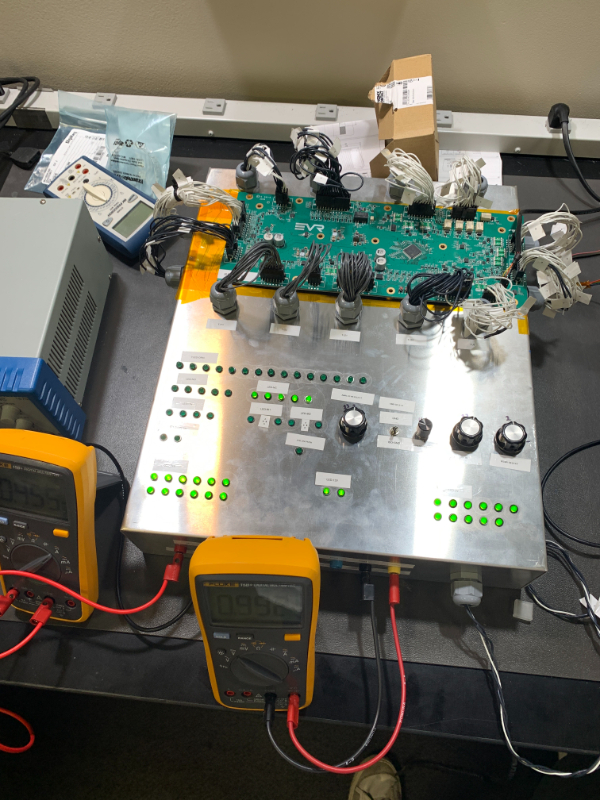

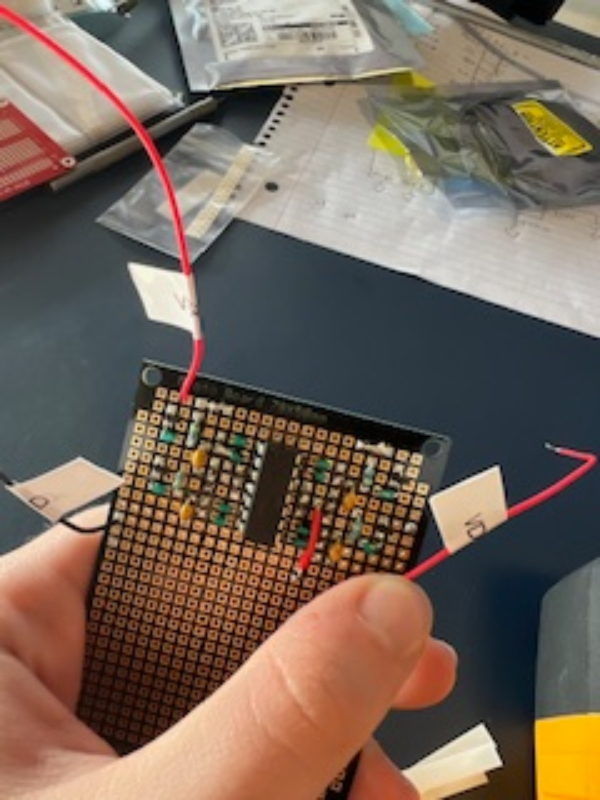

During the first few weeks, I focused heavily on soldering and modifying circuits for testing purposes. This included learning surface mount soldering for smaller components, primarily 0402 and sometimes 0603. In the subsequent weeks, I participated in building an electromagnetic emissions chamber from scratch. Following that project, I worked on creating protoboards, laying out various components to develop prototypes for multiple projects. One of my tasks included building a test box to verify that our PCBs were outputting the correct voltages under different configurations, as shown in the picture below. My most recent project involves reprogramming and testing 200 devices to troubleshoot an issue a customer has been experiencing. These devices are set to different configurations and tested under various scenarios to replicate and resolve the field issue.

Controls Engineering Co-Op at Adient

Zachary

Major: Electrical Engineering

For this semester of my Co-Op, I had several projects. All of these projects were related to PLCs and HMIs. Every PLC and HMI that I worked with was Allen Bradley. One biggest projects that I worked on was updating all of the PLCs to their latest version. This helped the plant be more standardized and allowed IT to support fewer firmware versions. I also got to create screens on HMIs so that operators and maintenance could print test labels out of printers. This was important to help troubleshoot problems with printers. Finally, I also got to write my ladder logic in the PLCs. For this project, I wrote code to send messages to the HMI to display the status of the cell.

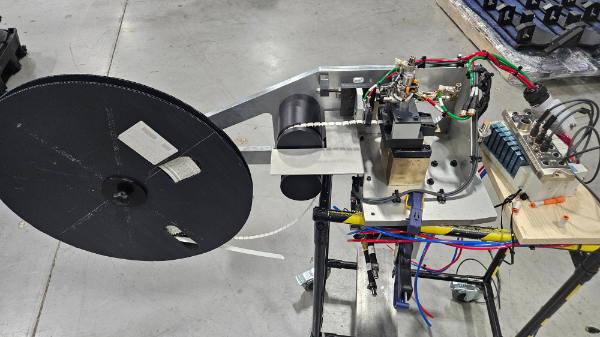

Mission Design and Automation Co-op Experience

Marcus

Major: Electrical Engineering

I worked on two different projects throughout my Co-op experience that provided me with very different experiences. The first project I worked on I was able to be the sole controls engineer on the job and was able to see the project through from start to finish. This meant I was able to get the time in preliminary software's such as AutoCAD electrical working on the prints, to working on the PLC and debugging on the floor, to seeing the customer come in and be very pleased with their runoff. The second project I worked on was a much larger project where I had the pleasure to work alongside a handful of other controls engineers also on the same job. This variation in job size throughout the rotation was something I really enjoyed and am extremely glad I was able to receive.

Read More About Mission Design and Automation Co-op Experience

Working in L3Harris's CAS department

Izik

Major: Electrical Engineering

I learned quite a bit about the flight recorders that L3Harris makes along with some of their other product lines. I was tasked with a good mix of production issues and then improvement projects that helped the production line and test engineering department as well. The main task was updating documentation for a test station and building it from the documentation I made.

Second Co-op Rotation

Jason

Major: Electrical Engineering

The tasks that I was assigned to do was to write software tests, find bugs in a system, and building products.

Co-op at Phase 1

Isabelle

Major: Electrical Engineering

At Phase 1, I worked on GPS trackers, linear motors, PCB designs, and schematic capture. These all were huge applications to the projects I helped complete.

A Great Environment

Ian

Major: Electrical Engineering

During my internship I was able to get an fpga program that runs MAPS (Modular active protection system) up and running. I got the same fpga with different firmware to send and receive data over TSN (time sensitive networking), and I designed a gui application from the ground up that would create configuration files for a bridged endpoint.

Service Engineer Co-op

Mark

Major: Electrical Engineering

Over the entirety of my co-op rotation, I completed two main tasks. The first task I completed was programming for a machine that aided in the assembly of luxury car grills. The main thing I did was help use a LIN protocol to set the software for these car grills. The other task I completed was to provide service to various customers when a problem arose. This gave me a variety of experiences in problem-solving.

Koops Automation Mechanical Engineer Co-op Experience

Carter

Major: Electrical Engineering

Throughout my co-op at Koops Automation Systems, I primarily worked on CAD, designing custom automation solutions. From adding fasteners to creating parts, I designed automated machines to increase production and lessen the manufacturing costs of various products.

Read More About Koops Automation Mechanical Engineer Co-op Experience

CO-OP in Electrical building design

Joseph

Major: Electrical Engineering

This semester I helped with a Red Arrow project that were apartments in Detroit Michigan. I work on some schools helping the K-12 group, most of my recent types has been working on Washtenaw Armory, Dearborn Inn, and Eden Park which is a park in Detroit Michigan. Most of our projects are in metro Detroit because the company is based in metro Detroit. However, there are some projects that are in Grand Rapids and Muskegon. As an electrical CO-OP, I placed outlets on plans, placed lighting equipment on plans, created circuits for the buildings to use and did lighting calculations which are calculation to do to make sure there is enough light in an area. A lot of our work is designing based on what is allowable by the code standards in Michigan.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.