Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Final Engineering Co-op Experience

Abigail

Major: Mechanical Engineering

This rotation I spent each 5 of the 15 weeks in different departments. First, I was in project management where I learned how to effectively communicate with customers and about different processes. The second rotation I was in was process engineering where I got to see more of the electrical side of things. Finally, I got to spend time in tool design learning about different tools in some of our machines and how the program the team used works.

F25 Third Co-Op Rotation

jack

Major: Mechanical Engineering

During my third rotation at HermanMiller, I've been given greater responsibility when designing fixtures and assemblies when compared to previous semesters. Often I was given a project, where then I was responsible for contacting the customer, conducting design reviews, and giving oversight to the machine builders after the design is released for assembly.

Magna Mirrors Co-op as an OSM Intern

Vincent

Major: Mechanical Engineering

As I worked for Magna mirrors the tasks, I was given had such variety throughout the semester. Some of these tasks include various methods of testing using the Instron to measure force or tension. Measuring the vibrational frequency of how the mirrors behave on the road in certain conditions. As well as even being given a specific project to create a fixture attachment to verify how many cycles some mirrors have completed in a chamber.

Co-Op 3 Magna Mirrors

Ammar

Major: Mechanical Engineering

During my 3rd co-op rotation, I supported multiple engineering activities within the product development and manufacturing processes. My work included assisting in design validation testing, documenting test results, and troubleshooting mechanical and electrical issues on mirror and vision-system components. I created and updated CAD models and engineering drawings, supported build events, and helped implement design changes based on testing and customer requirements. I also assisted with root-cause investigations for component failures, contributed to fixture improvements, and coordinated with cross-functional teams, quality, manufacturing, and program management to ensure issues were resolved quickly. Additionally, I took on data collection and analysis tasks, organized test/inspection documentation, and maintained clear communication with senior engineers to keep project timelines on track.

Fixture Design & Product Testing Co-op Review ý Navico/Lowrance & Lenco Systems

Luke

Major: Mechanical Engineering

During this co-op rotation, my primary responsibilities centered around hands-on engineering support within the test lab. I designed and built multiple test fixtures for new product development and product verification testing, including large welded steel assemblies and custom machining work. I also completed repairs and upgrades to existing fixtures to extend their usability and improve testing efficiency. In addition to fixture work, I contributed to improving and updating shop equipment and machinery, including tuning and upgrading the large-format 3D printer and performing general shop optimization tasks to support daily testing operations.

Read More About Fixture Design & Product Testing Co-op Review ý Navico/Lowrance & Lenco Systems

Co-op Rotation Semester 1

Matthew

Major: Mechanical Engineering

Some of the tasks I completed during my first co-op rotation were updating various designs of wash arches and components, updating prints by taking feedback from the production and service teams about pain points that need to be addressed. A larger project I took on was to update and redesign our in house built pressure washer that we provide should our customers need it.

Co-Op at Met-L-Flo

Ryan

Major: Mechanical Engineering

During my first semester of co-op at Met-L-Flo, I spent a significant amount of time on the production floor, gaining an understanding of the processes the company uses to manufacture parts. During my time on the production floor, I learned everything to do with casting. This included making the molds, cutting open the molds, casting the parts, finishing the cast parts, and finally shipping the parts out. In addition to working on the production floor, I also did some design work for both outside the company and internally. This was quite a challenge as the designs were left almost completely up to me with only a small amount of guidance. I think this challenge was good.

EGR 290 at Vibracoustic

Jacob

Major: Mechanical Engineering

As an Application Engineering Co-Op at Vibracoustic I was exposed to a large range of tasks including the development, creation, and testing of parts, developing relationships and collaborating with customers, and working closely with all support functions to meet customer demands.

Design Co-op

Kaden

Major: Mechanical Engineering

As a design co-op, the main focuses were learning new design software and 3D scanning parts as well as 3D printing many parts. The two-design softwares are CATIA and Siemens NX, as a co-op, one will learn one or the other and also fulfill any 3D scanning requests or 3D printing requests from other engineers.

Viant Medical: First Co-op Rotation

Alex

Major: Mechanical Engineering

During my time as a co-op student at Viant Medical, I have helped with many different projects and tasks.

I was on the new product launch so I was also able to train operators for product launch. I helped build devices, work on documentation, and build necessary fixtures needed for my line.

Co-op Rotation 1

Cooper

Major: Mechanical Engineering

I was responsible for multiple diagram deliverables, including HVAC zoning maps and piping and instrumentation diagrams for what I would consider to be large commercial facilities. For both of these projects I also visited the site to help assess the systems. I also assisted in designing the duct layout for a smaller building, setting up existing HVAC equipment in software, and updating company software templates in order to improve workflow.

AirLife Engineering Co-op Rotation #1 Experience - EGR 290

Isabelle

Major: Mechanical Engineering

As an engineering co-op, I had the opportunity to work on a variety of tasks and projects to support product improvement, testing, and validation. I gained experience testing products in the engineering lab, writing my own study to explore a product, and working with the test lab to design a new testing fixture. As part of the rotation, I had the opportunity to learn about other areas of the business and observe how different departments, such as marketing, regulatory affairs, engineering, and sales, work together to run a successful medical device business. When testing in the lab, I was tasked with setting up tests, collecting data, reading testing protocols, and following ISO and other medical standards. I used equipment such as the Instron for some tests, but the majority of tests were performed with pressurized air and were specific to testing airway medical devices. When writing my engineering study, I gained product knowledge, developed test methods, performed testing, solved issues that arose during testing, and analyzed data. I also got to work with the test lab engineers and lab technicians to design a test fixture for leak testing that improved efficiency and precision. During my co-op, I performed testing for different medical devices and worked closely with other engineers to improve products to uphold AirLifeýs high quality standards and ensure our products function above and beyond expectations for customers.

Read More About AirLife Engineering Co-op Rotation #1 Experience - EGR 290

Summer 2025 Co-op

Kolton

Major: Mechanical Engineering

I worked as a controls intern and was tasked with writing and debugging code. I was also tasked with setting up device IP addresses and teaching robot maneuvers.

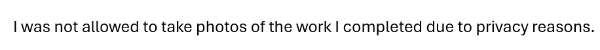

Co-Op Rotation 1 - Max Kolenda

Max

Major: Mechanical Engineering

I wore many hats at Air Master Systems during my first rotation, mostly within the space of casework, which is where cabinets fall under. I worked on many ECNs (engineering change notices) which are updates and fixes to existing products. These allowed me to interact with many employees, including on the floor, in order to get the best feedback possible.

I also worked on prototyping with my supervisor, which included assembly of a locker system and load testing and production of shelving for a book cart system. This load testing is pictured below.

On top of this, there was emphasis on an 8D improvement group, which invested time into implementing a new naming scheme and catalogue pages for the existing company shelving systems.

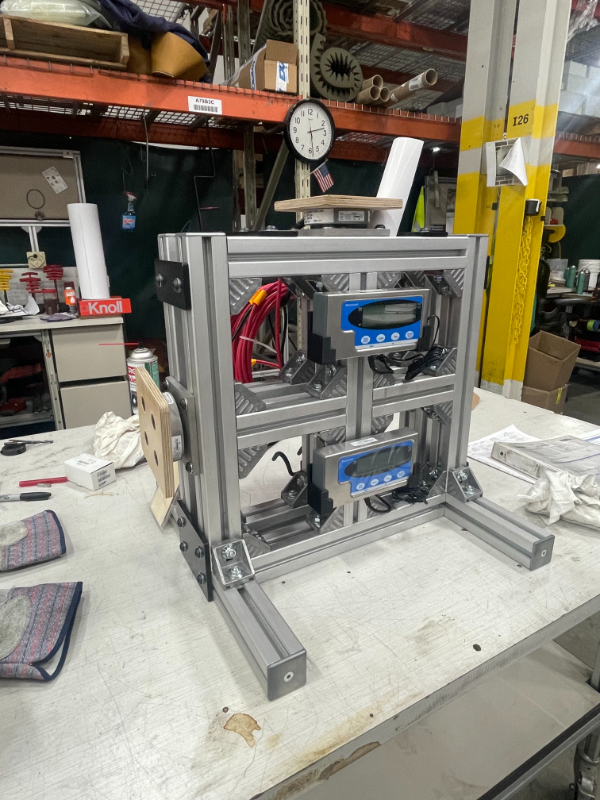

Creative Mechanical Design

David

Major: Mechanical Engineering

Designed an entire gameboard for intern project robot enclosure that holds parts in reliably the same place for the robot to pick, senses when parts are present, and actuates a rotating door based on programmed criteria. Detailed and ordered all parts necessary, redesigned as needed, supported controls engineers where necessary.

Designed end of arm tooling for collaborative robot that grabs hold of cups and fills them with beer of various kinds.

Magna Mirrors Co-op Rotation #3 - EGR 490

Tyler

Major: Mechanical Engineering

Throughout the course of the semester at Magna, I was involved in a variety of projects and tasks that were assigned to me. These projects consisted of benchmarking competitor products, operational checks on products, designing test fixtures, building and testing prototype products, along with running the additive manufacturing room with both FDM and Resin 3D printers. Additionally I would create reports and documentation to provide additional information in terms of benchmarked products along with tested parts for the various projects I was assigned.

Final Rotation - Navico Group

Brett

Major: Mechanical Engineering

A few projects that I have completed this semester include multiple fixture designs and assemblies, running a thirteen trolling motor prototype build, and rapid prototyping to rework unfinished products.

Automation Engineering Co-op at Miller Knoll - EGR 490

Jonah

Major: Mechanical Engineering

During my time as a co-op at Miller Knoll I have helped with many different projects on the manufacturing floor. I have helped with machine installation, created layouts in AutoCAD, worked with our operations, MES, controls, and quality teams in order to improve the efficiency of our processes.

Read More About Automation Engineering Co-op at Miller Knoll - EGR 490

Engineering Co-Op Rotation 3

Benjamin

Major: Mechanical Engineering

This semester I worked in solidworks to design a couple different machines and redesign some parts of other machines. I worked on a machine that makes a headliner for a Honda vehicle, and a large machine that assembles air compressors. half of my day was taken up by solving complex design issues and half was doing tedious "paperwork" style tasks.

Summer 2024 Internship

Nathaniel

Major: Mechanical Engineering

I helped program and debug a machine that made coolant reservoir bottles.

S24 First Co-Op Rotation

jack

Major: Mechanical Engineering

During my first rotation, I mostly worked on making small additions to larger assemblies that the team has been working on for months. For example, if a change or modification is requested for an existing station on the floor, I would be tasked with designing and releasing my assembly.

Magna Mirros Co-Op

Ammar

Major: Mechanical Engineering

During the Co-Op at Magna Mirrors Engineering Center, I engaged in a variety of tasks and projects that spanned testing, machining, design, and collaboration. I conducted several tests to ensure product reliability and usability, including temperature, vibration, dust, and impact tests. I gained hands-on experience with machining and assembling components, working with CNC technology, and creating prototypes. My design work included developing models and proposals for custom fixtures and enclosures. Additionally, I finalized technical reports, created documentation to assist future interns, and collaborated with different departments to design and test parts for various projects.

First rotation summer 2024 Co-op

Stefan

Major: Mechanical Engineering

As a mechanical engineer in the inside mirrors division, I was tasked with finding solutions to problems or assignments given to me by other engineers. These assignments often consisted of designing/building parts that aid in different methods of testing mirrors, testing the functionality/durability of inside mirrors, and collaborating with team members on enhancing my skills and knowledge as an engineering student.

Winter 2024 Aspen

Josh

Major: Mechanical Engineering

I was (am) responsible for various manufacturing machines and processes. I am responsible for 3D scanning, scan to CAD software, 3D scanning inspection/validation software, CNC programing software, CAD modeling software and 2D vision inspection systems.

Second Co-op Rotation

Dante

Major: Mechanical Engineering

Small-scale production while investing in the improvement and changes in the production process while helping in the applications and quoting areas as well.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.