Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Co-op 2

Trevor

Major: Mechanical Engineering

I assited in a varity of product launches from ordering tooling, fixtures, and problem solving. Also I supervised an area and assisted in day to day operational issues.

2nd Co-op Rotation

Ethan

Major: Mechanical Engineering

My main task was running laser cell production which included cleaning, repairs, and other general maintenance on the 6 laser cutter machines as well as the Sort Ný Etch. I also completed side projects of 2D CAD and gcoding, 5s projects, cycle time improvements, welding, duct work, motors, etc.

Second Co-op Rotation at Axis Automation

Zachary

Major: Mechanical Engineering

A large amount of my time this semester was spent working on tooling station and robot end effector designs. This includes but is not limited to initial designs, internal and customer design review meetings which require design changes, compiling documentation for the components to be machined and built, and overall job documentation for the customer.

Viking Products Incorporated Second Co-op rotation

Darwin

Major: Mechanical Engineering

Over the course of my second rotation, I was able to take on more responsibility in creating RIR work instruction for different parts as well as maintaining quality of the gauges registered in the company. I also was able to expand my knowledge of the Keyence by creating more Keyence programs for parts with dimensions that are hard to measure with a caliper or micrometer. Moreover, I was able to utilize my solidworks skills by creating a covering design needed for one of the machines used for part inspection

Read More About Viking Products Incorporated Second Co-op rotation

Second Rotation of Co-op at Panduit

Nick

Major: Mechanical Engineering

During my rotation, I worked on several tasks. One task involved designing an informative chart for Panduit customers and employees to easily access information on ferrules (which is a product that reinforces stranded wire), their compatible tools, and optimal usage. Moreover, I developed a solution for a testing fixture, enabling engineers to conduct tests on one of our tools. Also, I contributed to the ideation, design, and testing of a product that secures cables in the case of a short circuit event, or disaster. This included collaborative brainstorming, and working directly with an engineer to model, fabricate, and test different solutions. I was able to help design multiple prototypes, then later see it in real life after it was made. In addition to my tasks, I was able to visit one of Panduitýs toolshops. This toolshop is dedicated to research, development, and rapid prototyping. I observed specialists in sheet metal fabrication, 3D printing, EDM machines, CNC milling, and molding design.

Applications Engineering at JR Automation

Jackson

Major: Mechanical Engineering

As an applications engineer, I was tasked with quoting projects for customers. I organized and led meetings attended by different departmental management and leads focused on introducing requests, brainstorming and developing concepts, putting costs to a project, and reviewing proposals with business management and executives. Applications engineers also meet with customers and vendors, working together to create the best possible solution to a problem introduced by the customer. In between meetings, I was tasked with further concept development, drawing up concept imagery, doing preliminary design work, creating concept simulations, and writing the proposals that were to be sent to the customer.

Co-Op Year 2 @ Autocam Medical

Brady

Major: Mechanical Engineering

On a day to day basis I work on doing Non-Conformance Reports to investigate why certain parts in the manufacturing process fail to meet expectations. I was also responsible for making sure the automatic straightening robots stayed running throughout the day.

Larger scale projects I worked on was generating an automatic weekend scheduling assistant in excel. The excel file would use each employees availability on weekends (that they get to choose, weekends are not required so it was all bonus time for the machinist) as well as inputted weekend job data such as duration, quantity, machine ID and Job #. A table would then generate assigning available employees to time slots to reload the machines based on their personal schedules to keep them running as frequently as possible on the weekends. The table helped to allow the flow of communication as a simple image could be emailed out and every employee would know what times to come in at.

Another large scale project I worked on was designing a custom fixture plate for one of our grind machines at the plant. A new and faster method of swapping jobs was going to be implemented on the machine, but there was no appropriate way to mount the system to do it. I got to design a fixture plate from the ground up to adapt this system onto our machine.

Trane Technologies Co-op - Rotation ll

Skyler

Major: Mechanical Engineering

This rotation my responsibilities were expanded beyond B-team engineering to A-C team engineering. I mainly focused on units from our Clarksville plant by carrying out modifications such as Variable Air Volume (VAV), Electric heat, and Modulating Gas Heat. Each unit that came through the door was assigned to a group of engineers depending on the modification. It was then the engineer's responsibility to design, draw, create paperwork, and request parts for the job. Drawings varied in complexity. Some could be used from previous jobs while others needed to be designed from scratch. The paperwork consists of a Special Unit Label, installation Operation and Manual document, and Parts List which were all customized for the job. Programing was completed in Tracer TU and used function blocks rather than lines of code. Custom components were requested depending on the job and the Bill of Materials (BOM) is generated and sent to the materials team. Additionally, every job must be audited by another engineer to ensure correctness. This helped me personally since it gave me great exposure to an array of units and modifications.

TGW co-op

Brendan

Major: Mechanical Engineering

for a project engineer at TGW it is normal to be working on drawings in AutoCAD for the customer along with going on site and doing site surveys or just helping the install team while they are installing the system. The job is broad and many different tasks you have never done before can come your way, this can range from permitting, install drawings, and many others.

Design and Analysis at Navico Group

Brett

Major: Mechanical Engineering

A few tasks and projects that I worked on over the course of the semester included fixture design and construction, new product testing, PLC controls integration, python coding, and assisting in prototype builds.

IPM Co-Op - Rotation II

Kyle

Major: Mechanical Engineering

As a mechanical engineering Co-Op, I was tasked with designing both product and palletizing conveyor for this rotation. This included drawing up the conveyor in SolidWorks, creating installation instructions or drawings for the installation teams, and detailing parts. Additionally, I helped test robot cells on the shop floor and assisted shop floor workers design and modify conveyor when defects or misalignment of parts prevented the conveyor from working as designed.

Co-Op Rotation #2

Pierce

Major: Mechanical Engineering

Over the course of this semester's Co-Op I was able to work on CAD projects, create my own innovation project, perform rapid prototyping via our 3D printers and did validation testing in the lab.

2nd CO/OP at NN Inc.

Connor

Major: Mechanical Engineering

I worked as a manufacturing quality intern engineer providing assistance to machinists and operators, while learning and working with the area engineers and managers on day-to-day operations. Some tasks included designing and documenting new processes, experimenting new tools, continuous improvement on the machine floor, and analyzing data results.

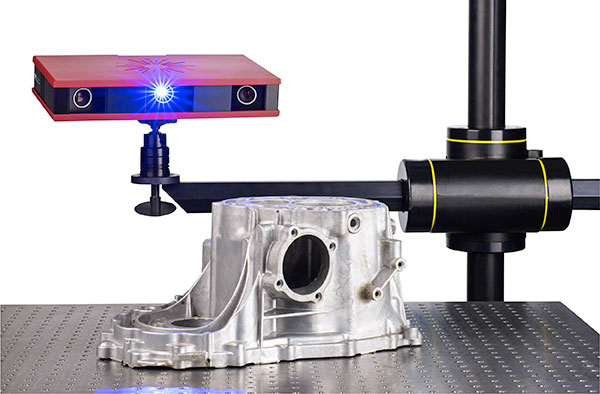

My Experience at Magna International

Zachary

Major: Mechanical Engineering

I was the Verification and FDM team leader. In this position, I worked on 3D scanning as well as rapid prototyping.

3rd Rotation

Dawson

Major: Mechanical Engineering

This rotation I was able to step into the light of the Systems team, where I helped work on Avionic's systems specifically dealing with dynamically tuned gyros. The goal of my internship what to help manage their work instructions for their manufactuirng operations, as well as help work on testing and analysis work that needed to get done for the team. We are scarse on mechanical engineers, so I was able to really take reigns to help get things done.

Co-op Rotation 3

Lucas

Major: Mechanical Engineering

I worked with the engineering team on designing the assembly station for a new office chair that'll be introduced around spring of 2023. I was involved with designing the pallet that holds the chair as it goes down the assembly line and the seat press assembly station.

aMDI Co-op Experience

Co

Major: Mechanical Engineering

I worked on creating a protocol and execution of an accelerated aging study, a design history file (DHF) remediation project, and worked to promote innovation through liquid photopolymer additive manufacturing (3D printing).

Blackmer Co-op

Benjamin

Major: Mechanical Engineering

During the semester I was challenged with many tasks such as completing Engineering Change Request and Notices, BOM changes, configurator updates, SolidWorks CAD model and drawing design, completing hands on work such as building and tearing down pumps and compressors, and running tests on units.

3rd Co-Op Rotation

Jacob

Major: Mechanical Engineering

During this Co-Op rotation, the majority of my tasks were quality based. A new product line was being launched for a customer which involved the interior mirror not only being a mirror but also an LCD that is capable of showing an image from several cameras around a vehicle. Developing a new product comes with many unexpected problems in which large-scale studies need to be done to discover their source. This was my main task. A secondary project was re-creating a suitcase tester used for testing mirrors for functionality out on the production floor. While re-creating it some improvements needed to be made which led to creating of new 3D models, and a bill of materials.

Trane, Creative Solutions Team, Electrical

Dakoda

Major: Mechanical Engineering

I mainly focused on D-team engineering which are chillers that come from pueblo like the RTAC, CGAM, and ACRB. I focused on pump packages, dual point power and waterside economizers. Additionally, each electrical drawing needs to be audited which falls pretty heavily on the intern. Finding mistakes in others works helped to point out potential mistakes of my own. Each job can be broken down into 4 parts. Purchasing, drawings paperwork and programing. Purchasing includes adding all items on the Bill of Materials (BOM) to a requisition program JobBOSS and sending it to the materials team. Drawings includes updating and adjusting previous jobs to meet the new design requirements or starting an new drawing from scratch if nothing similar is available. Paperwork includes special shipping labels, installation and operation manuals and test logs built for the customized changes to the unit. Programming includes using Tracer TU to adjust previous programs to meet current requirements.

3rd Co-op Rotation at Ravenna Ductile Iron

Jack

Major: Mechanical Engineering

- Cleaning and putting away pattern plates

- Operating a jib crane and hi-lo to put away pattern plates.

- Improving the current tools to run better(this is done in CAD).

- Designing how a customers part will fill and solidify within a sand mold (this is done in CAD).

- Quoting and launching tools with different pattern shops.

- Making PowerPoints for modifications to be made to pattern plates.

- Submitting .stl files for sand mold filling simulation.

- Analyzing simulation results and making changes in CAD accordingly.

HVAC Equipment Sales at Trane

Sydney

Major: Mechanical Engineering

My main responsibility is generating equipment submittals, which document what equipment and accessories a customer has ordered, along with performance. The process includes reading building plans and specifications then verifying that Trane supplies everything the customer needs. I also generate quotes for equipment replacements. This involves translating the old unit model number(s) to a current Trane model, checking what units we have in stock, and pricing the units.

Fall Co-op Rotation

Danielle

Major: Mechanical Engineering

I was the lead on several equipment/assembly line moves. I contacted suppliers and sales representatives for quotes of new equipment. Prepared documents and background for implementation of new tools/processes. I owned an assembly line, and was the main point of contact for day to day issues on the line, or ergonomic improvements. I also led weekly meetings for redesigning an area to help with flow, safety, and ergonomics. I designed a bunch of solutions on Solidworks for different problems. For example, press brakes needed new tables, and brackets for new light curtain distance. I designed and had all of it made up and reconnected. I also designed carts, deflectors, tables, guarding on machines etc. I did some plant layout as well.

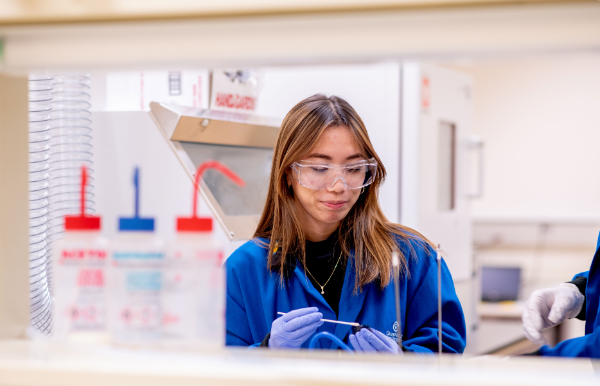

Third Co-op Rotation at Rose Medical

Jenna

Major: Mechanical Engineering

My third co-op rotation consisted of developing dipping and molding processes. I was in charge of learning how the temperature, pressure, and time settings on the machines affected the outcome of the silicone molded parts. Learning the effects of these settings allowed me to develop processes for multiple silicone molded parts and ship samples to the customers. Additionally, I was able to run my own project this semester. I was in charge of creating all of the specifications and documents and leading weekly meetings with the customer where I kept them informed on the progress of the job. I was able to develop the manufacturing process, ship sample parts to the customer, and run a production run.

OSM Co-Op

Benjamin

Major: Mechanical Engineering

My workload consisted of creating prototype parts and mockups, temperature testing, durability testing, driving the mirrors, and other smaller projects that follow the guidelines of research and development

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.