Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

EGR 490 Co-op Rotation III

Rhianna

Major: Biomedical Engineering

I ran cycle time studies for two different production lines, inside and outside of a cleanroom. I had also created and/or edited various documents, such as work instructions, production routers, and visual defect libraries, to make them easier to read and provide better explanations for steps. I had also developed process flow diagrams for two production lines to show the steps for making each finished good from materials coming in to shipping to the customer. Lastly, I have ordered spare parts for multiple production lines using an ERP system to place requisitions and contacted suppliers to fulfill the orders.

Third Co-op Rotation as an Engineering Intern at Viking Products, Inc.

Cebrina

Major: Biomedical Engineering

As a third rotation co-op engineering intern, I helped a lot with prototyping and aided in preparing parts for production. This involved physical testing and dimensioning of the parts to analyze the performance of the parts in their initial phases, part inspections, standard documentation, and working with overseas suppliers in charge of the manufacturing of the parts to assure the processing of the parts. I wrote work instructions, put together PPAPs, and worked heavily with CAD drawings and modeling. I also worked with customer quotes, making preliminary drawings and performing drawing comparisons to analyze customer requirement specifics and part revisions. As interns, we also work with shipping, pick up and deliver parts, and help the warehouse team with inspection and sorting of parts as they come in and get prepared for shipping.

Read More About Third Co-op Rotation as an Engineering Intern at Viking Products, Inc.

My Final Co-Op Rotation

Emmah

Major: Biomedical Engineering

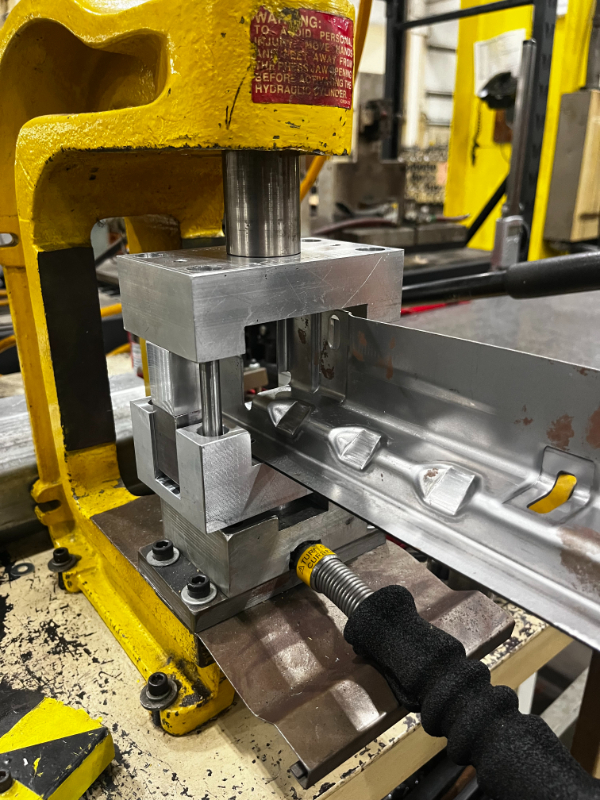

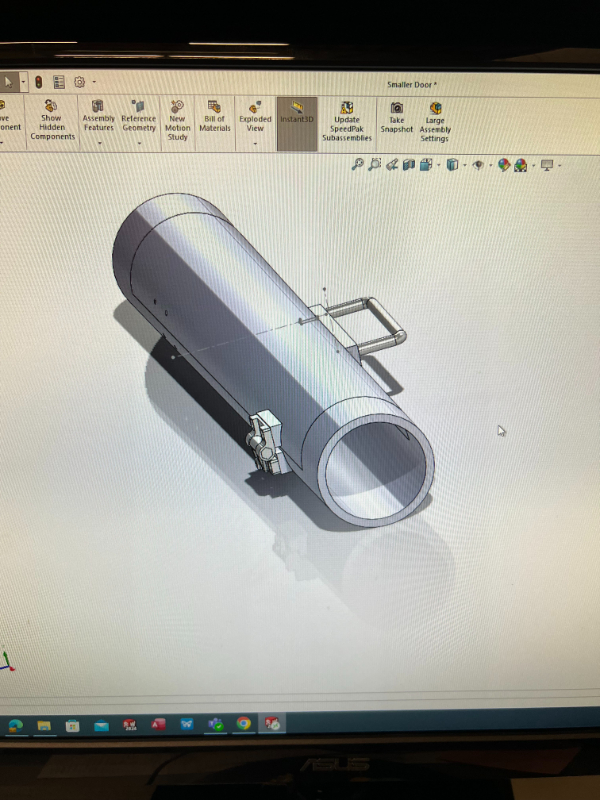

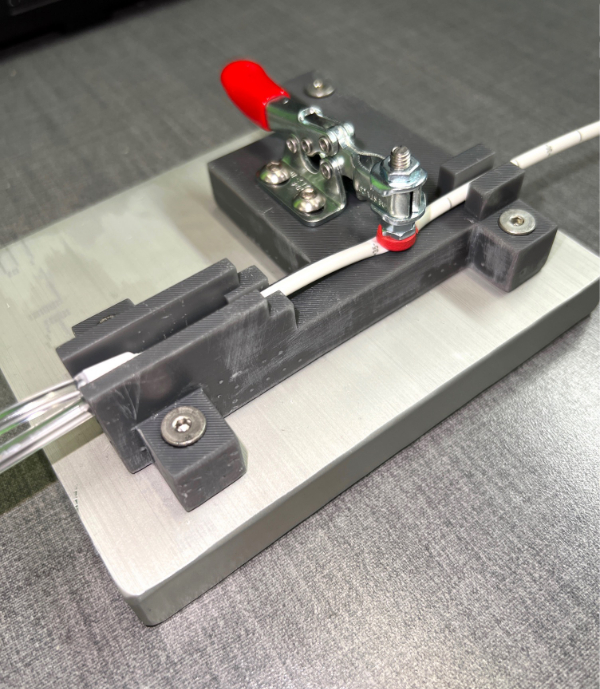

I have completed many tasks this semester. These tasks include CAD projects where I have designed a CMM mount for a gear rack which is a part produced here, a pre-assembly fixture poka-yoke, a trunnion gauge block, a rivet funnel, and a rivet pullout force fixture. These are all made or in the process of being made by toolroom to be used on the plant floor. I have also performed capability studies on multiple new parts to include them in the PPAP packages. I also made a color chart for die CAD and organized all of the company PPAP packages by moving them into the PLEX software. There are various other tasks I have completed but they are a much smaller scale, such as work instructions or inventory.

Viant Medical Co-op Rotation 1

James

Major: Biomedical Engineering

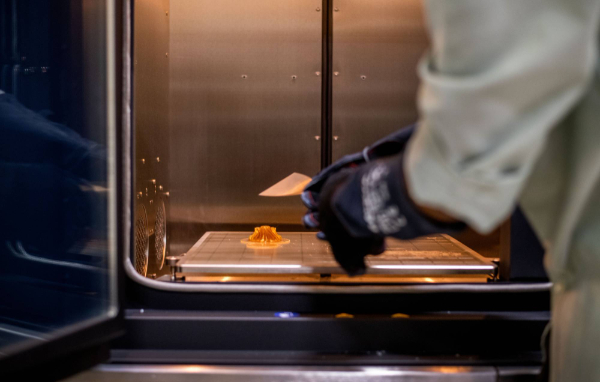

During my time on the line, I completed a variety of tasks and projects that ranged from technical documentation to hands-on fixture development. I improved existing work instructions for several stations to enhance clarity and usability for operators, and I created new documentation to support the integration of equipment into the line. These efforts ensured that both legacy and new processes were clearly communicated and easy to follow. I also authored engineering build reports to verify that components from new suppliers met customer specifications and functioned properly within the final product. On the hands-on side, I designed and 3D-printed a fixture to hold five work-in-progress pieces, improving workflow and organization at the station. Additionally, I evaluated other fixtures and prepared them for production, ensuring they were ready for deployment and met operational standards. These projects reflect a balance of technical writing, process improvement, and practical engineering support.

DornerWorks Co-op 1

Emalee

Major: Biomedical Engineering

I have been doing a lot of real project work at DornerWorks. Specifically, I have spent my time writing code in order to send messages to a prosthetic hand. I have had the opportunity to work along other engineers as well as independently.

Viant Medical Fall 2024 Co-Op Experience

Zephaniah

Major: Biomedical Engineering

I was on an a New Product Introduction (NPI) line that will produce a remote subcutaneous suturing and stapling device. Tasks related to this included executing test method validations on the line, Process development and assembly aid design, and designing programs for automated data collection and analysis.

3rd Co-Op rotation at Rose Medical

Justin

Major: Biomedical Engineering

For the majority of this rotation, I worked to update and redesign fixtures used in production so they were easier to use. Another project was to analysis the measurement tools and methods in place for a product and report the results back to the customer. I also took measurements on incoming components when a new shipment arrived.

EGR 490 Engineering Co-op

Halle

Major: Biomedical Engineering

During my third engineering rotation, I led a quality plan to remediate a product within our category. This involved updating documentation to ensure alignment with ISO standards, planning verification and validation testing, managing tasks, and creating a detailed project timeline. Additionally, I supported design changes for another product, which included conducting testing, analyzing results, and presenting findings to upper management and the cross-functional project team.

Engineering Co-op Rotation 1 Experience

Cebrina

Major: Biomedical Engineering

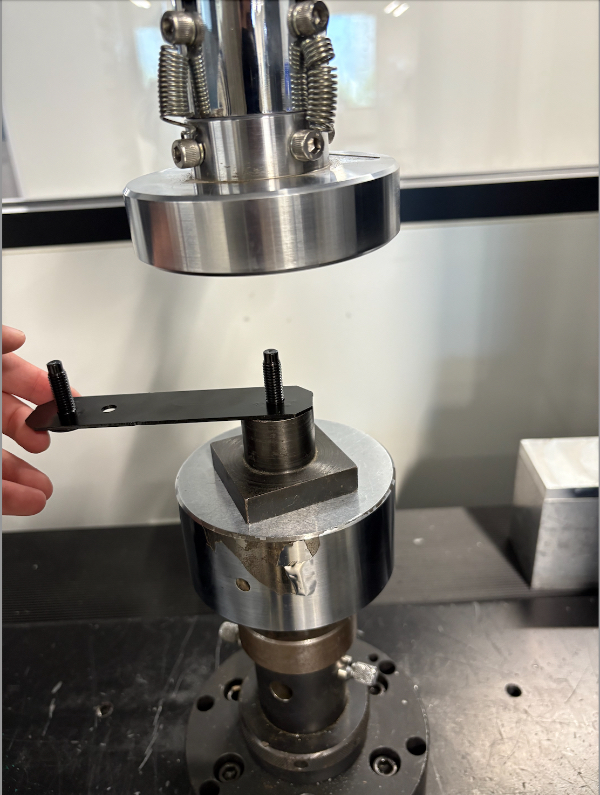

Rotation 1 of the co-op is focused on the testing process of parts. For this, we were tasked to do dimensionals of sample parts, Instron testing, hardness testing, torque testing, help put together PPAP packages that prove the part's quality, sort through parts for visual inspection, 3D print parts, create work instructions showing how to check parts with particular pieces of equipment, check drawings to keep track of changes, put together estimated drawings, and helped other engineers with any tasks that they needed help with, including picking up and dropping off parts from other manufacturing companies.

Trane Technologies Engineering Co-op Rotation 2

Matthew

Major: Biomedical Engineering

I was in charge of keeping building graphics updated for the control projects, and creating or ordering new ones when they were needed. I also worked on a few projects to develop controls for buildings, and helped out the other engineers with drawings for their projects. Finally, I was in charge of handing the parts that came in for all of our projects and makings sure they were documented and stored correctly.

Read More About Trane Technologies Engineering Co-op Rotation 2

Third Co-op Rotation at Marketlab

Stephanie

Major: Biomedical Engineering

During my third rotation, I assisted my supervisor with completing some objectives for a recent business acquisition. I was responsible for creating a handful of work instructions and helping to transfer some of their BOMs into our system. I was also involved with a variety of miscellaneous projects, including product testing, 3D printing, designing a fixture for their screen printing process, creating technical drawings in SolidWorks, and more!

Product Engineer Co-op at Inrad Inc.

Morgan

Major: Biomedical Engineering

I spent my time designing, prototyping, and testing devices that are on their way to market. Along with design work, organizing research and testing to convey to the team was important.

Third Co-op Rotation

Cara

Major: Biomedical Engineering

I worked on additive manufacturing projects and operational and performance qualifications.

1st Co-op Rotation at Rose Medical: Winter 2023

Justin

Major: Biomedical Engineering

My first two weeks I spent a rotation of about 3 hours in the clean rooms to be able to see our processes and what Rose is capable of. From there I took the lead on two development builds for a new product transitioning from development to production at Rose. This involved doing much of the manufacturing by hand or with basic fixtures. Once these development builds were completed my work became focused on designing and qualifying new fixtures Rose would use to manufacture the the new product. In addition, I completed qualifications for the processes used in production.

Read More About 1st Co-op Rotation at Rose Medical: Winter 2023

Project Engineering Co-op

Nathaniel

Major: Biomedical Engineering

Being a smaller company, I completed a variety of projects, including research, product testing, developing manufacturing methods, and product development.

Final Co-op Experience at Viant Medical

Selia

Major: Biomedical Engineering

I wrote and edited several types of documents including but not limited to: component specifications, item masters, qualification protocols and reports, work instructions, fixture files, formal information collections, etc. I also owned several trackers for component procurement, drawing revisions, all documentation (500+) involved in the new product launch, and more. I worked closely with my project team on designing equipment and their stations with integrators to make them ready for the line and process development. Worked with supply chain to gather supplier information and documentation to get them as an approved supplier through Viant, ensuring they can meet all of the specifications needed by the customer on their drawings. I also created a tracker to track component inventory and first article inspection data.

Third Semester - Altus Industries

David

Major: Biomedical Engineering

As a third semester intern, I was given a fair amount of design work and assignments this semester. I was given a lot of responsible and hoping that it has lead my to a career with the company still.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.