My Final Co-Op Rotation

Experience Information

Employer: Stanco Metal Products

Job Title: Manufacturing Engineering Intern/Co-Op

Major: Biomedical Engineering

Received Credit: Yes

Paid: Yes

Abroad: No

Description of the Organization

Stanco Metal Products is a small family-owned manufacturing company in Grand Haven, MI with locations in South Carolina and New Mexico as well. It consists of many presses to stamp various kinds of metal products. There are also riveting stations, welding, assembly, and more. The offices are at the front of the building and the factory portion is at the back. Everyone knows everyone at this company and everyone is very welcoming/inclusive.

Description of the Tasks/Projects Completed

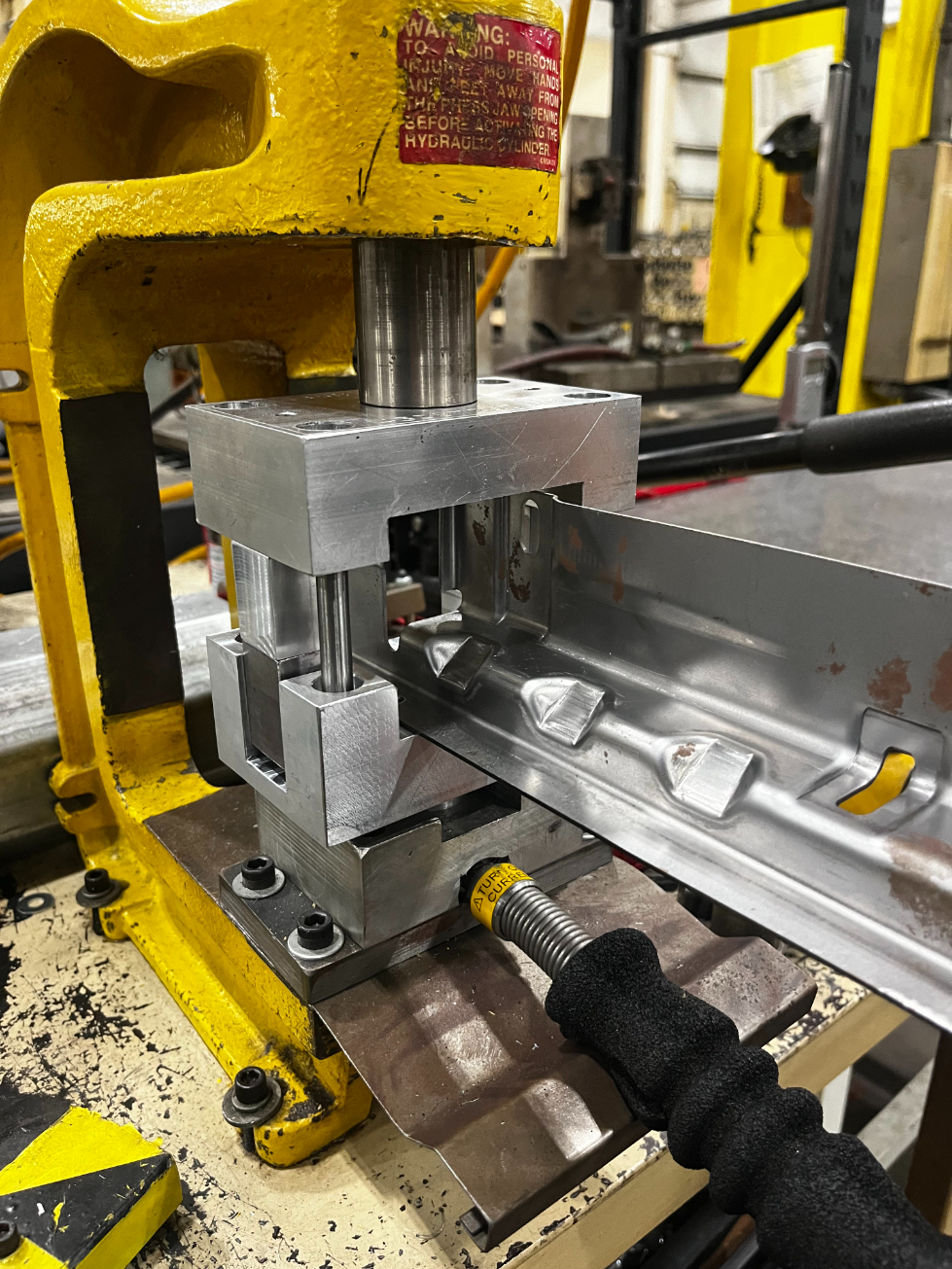

I have completed many tasks this semester. These tasks include CAD projects where I have designed a CMM mount for a gear rack which is a part produced here, a pre-assembly fixture poka-yoke, a trunnion gauge block, a rivet funnel, and a rivet pullout force fixture. These are all made or in the process of being made by toolroom to be used on the plant floor. I have also performed capability studies on multiple new parts to include them in the PPAP packages. I also made a color chart for die CAD and organized all of the company PPAP packages by moving them into the PLEX software. There are various other tasks I have completed but they are a much smaller scale, such as work instructions or inventory.

Skills/Knowledge Gained Through The Experience

I learned how to be more independent when working on projects but I also learned that I can always ask my supervisor for help if I need it. I have greatly improved my communication skills in a professional environment as well as my relationships in the workplace. This makes it so much more fun to go to work instead of it feeling like a chore. I have also learned that a design I make in CAD may work in CAD, but it will not always work in person. This has helped me improve my design skills to take into account the operators who will be using the gauges or fixtures.

Favorite Part of the Experience

My favorite part of this co-op experience was seeing how the material that I learned in my classes is applied in the real world. I used manufacturing processes, beam bending, CAD, critical thinking skills, Ansys, and more while working here. I also enjoyed how I got free reign on my design projects and got constructive feedback on all of my work. Most of the CAD projects I completed were made in toolroom and are used by quality technicians on the plant floor. I find it very cool that I get to see the work I created being used.

How the Experience Influenced Future Career Goals

Being in a manufacturing company instead of a medical company for my co-op has taught me more than I thought possible. My emphasis is product design and manufacturing so everything I have learned at Stanco I will use in my future career in a medical company. I have talked to multiple medical device companies for employment after graduation and they are all very impressed with the knowledge I have gained from this company. Overall this experience has made me so much more confident in myself and my ability to be a successful engineer.

Internship Format

In Person