Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

1st Semester Co-op: Gentex

Major: Product Design and Manufacturing Engineering I was tasked with designing, fabricating, wiring, and building a target thickness scanner to improve efficiency of cathodes used in the glass coating process. Measurements of the target cathodes were previously done by hand before installation and after their lifespan to measure erosion of the target (ruthenium/chrome). My design utilized a 3D scanning head running along a linear actuator that outputs dimensions and a 3D profile of the 9-foot cathodes. This will decrease the time for measurements and increase the accuracy.

Design for Change

Major: Product Design and Manufacturing Engineering During my experience at Magna I worked many prototypes that will eventually make it on cars. Being able to see the hard work on consumer product is a surreal experience. In addition, I was in charge of building display stands and benchmarking the competition.

Engineering Co-op 1: TMG

Major: Product Design and Manufacturing Engineering I managed the testing of the 18 model year Nissan Frontier truck. This included monitoring test results from applicable groups, ensuring events were completed according to schedule, writing and releasing weekly reports to directors, sr. managers, and other applicable personnel, and in the case that a failure occurred, I would be responsible for tracking countermeasure development. I was also assigned several additional projects which included tracking late orders from suppliers and presenting weekly status reports, building a vehicle quantity benchmarking database and developing vehicle quantity prediction formulas for future projects, revising/condensing/clarifying confidential vehicle camouflage guidelines, along with small tasks to assist my team when they were overloaded.

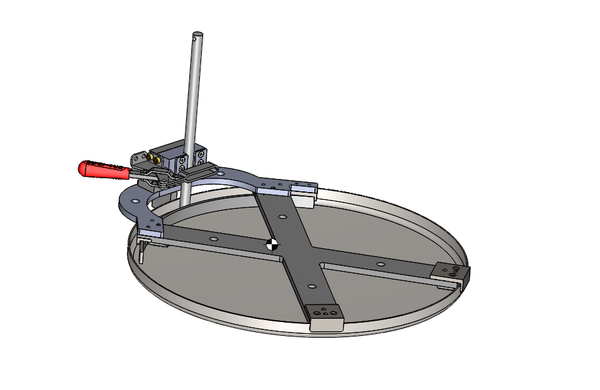

IPM Co-Op I

Major: Product Design and Manufacturing Engineering I have had previous experience with IPM outside of my first co-op, so I was able to hit the ground running with some new product development projects. As a Co-Op/Intern, you are expected to complete the full suite of task that any of the engineers would complete, including, but not limited, working with sales and project management to clearly define goals of the project, work with fellow engineers (both within your field of focus and not) to design a product or portion of an automated system utilizing Computer Aided Design, deliver manufactured components to mechanical assembly with the assistance of internal purchasing agents and local machine shops, a support the assembly and installation of designed equipment. Throughout the experience, the projects are "owned" by you, and you are responsible for every facet of the design, including attending important information gathering meetings, the ordering of components, and the support of testing and debugging equipment. However, your fellow engineers, as well as nearly the entire IPM staff are incredibly friendly and willing to help and answer any question you may have about the job function you are performing. Co-Op students complete work very independently, with knowledgeable and friendly people available to help facilitate learning in a team focused environment.

Yanfeng Automotive Interiors

Major: Product Design and Manufacturing Engineering This semester I worked in a plant as the manufacturing engineer on three door assembly lines. As part of that, I handled a wide range of tasks as they came up. This included working on the manufacturing line to gain experience, resolving safety and quality concerns, repairing machines as needed, leading a work re-balance to eliminate unnecessary production, and helping with on-going updates to equipment and processes.

2nd Co-op Rotation at Emerald Corporation

Major: Product Design and Manufacturing Engineering During my second rotation of co-op at Emerald Corporation I was able to take charge and lead a few new projects. One of the projects was to come up with a new way to ensure traceability on all of the parts that are painted on our paint line. I was able to talk with many different printer and label suppliers to determine a plan of action to implement printers on our unload side of the line. These printers will allow Emerald to place labels on every part which will include important information about that specific paint run. If we have a quality alert from our customer we will be able to quickly determine a root cause based on the information printed on the label. Along with the leadership roles I was still able to enhance my CAD skills by designing new fixtures and even making edits to our plant floor blueprint.

Co-op at Altus

Major: Product Design and Manufacturing Engineering As being the engineering co-op student at Altus, I have been given many responsibilities. I have tasks of creating and redesigning workstations so that the products could be assembled faster by our assemblers. I also deal with suppliers when there is a quality issue so that the issue does not occur again. I help with prototyping new products and I am including in discussions relating to the future of products and how we can develop our carts to be more successful. For being a co-op student, I have a lot of say in the development of our products.

Herman Miller Options Engineering Co-op

Major: Product Design and Manufacturing Engineering I engineer a customer's special order that has deviations from the standard furniture product. I choose which products I want to engineer prioritized by order date. It starts with research on the standard products and the changes that were quoted. Then, I create the appropriate CAD parts and drawings that are needed for the order. The bill of materials would be altered by creating new parts, adding existing parts, and/or removing parts in order to match the order. I self check all of my work, then pass it onto another engineer to audit. My product is then signed off and sent to the next step towards manufacturing.

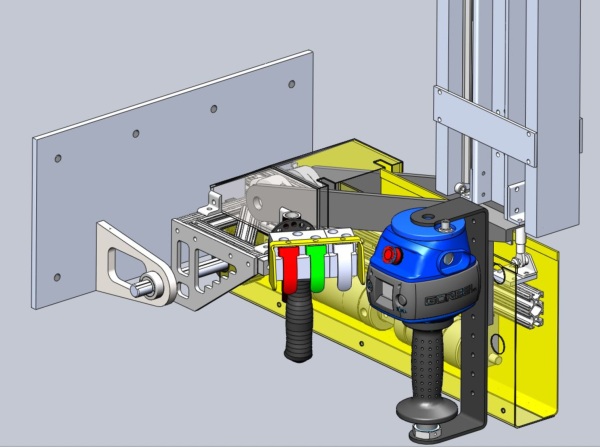

Koops Inc. Co-op

Major: Product Design and Manufacturing Engineering As a member of the mechanical engineering team, I designed the custom automation machines produced by Koops. Some of this work involved making modifications to existing machinery, while other work was designing completely new machines. During the designing phase, I was involved in design reviews with customers and collaboration with other designers.

Herman Miller - Manufacturing Engineering

Major: Product Design and Manufacturing Engineering I spent a lot of time developing a gantry-mounted lift assist device that operators could use to easily pick up heavy counterweights with vacuum cups and install them into units. I also had the chance to develop fixtures and enhance capabilities to assist operators in the manufacturing of new product. I worked on adding additional features and systems to an automated cell. Primarily, my projects were for safety or ergonomic related improvements. I would collaborate with internal and external toolmakers, mechanics, managers, and engineers to assist me in my project goals.

EGR Co-Op III

Major: Product Design and Manufacturing Engineering This is my third rotation of co-op with Hydro-Chem Systems, each having more responsibilities than the previous. Daily tasks included created sales and production drawings to relay information regarding installation and manufacturing. Projects included product redesign and process improvement.

Altus Industries Co-op

Major: Product Design and Manufacturing Engineering Because it was my first semester at Altus, I had to start from the very beginning and learn everything about the company. So the first month or so I mainly worked on the floor and was building the products. This helped me learn the parts, the assembling of the products, and just the products themselves. After this month, I began to transition into more responsible roles. I helped with product development, quality checks, and quickening the assembly process. For product development, I assisted with accessories that went on the carts and even brand new styles of the carts. The quality checks occurred when parts were showing up frequently with problems. I would go through almost all of that part and decide whether it was just a coincidence or if this was a problem that needed to be quickly addressed. With finding faster ways of assembling the carts, I was able to change some parts by contacting suppliers so that it allowed for a faster assembly

Yanfeng Automotive Interiors

Major: Product Design and Manufacturing Engineering This summer my main project was in supporting the advanced manufacturing team while they prepare for the transfer of three manufacturing lines from Michigan/Ohio to a new facility in Illinois. I spent time at the Ohio manufacturing plant to understand and document the line as it is today, helped to gather data for the design of the new line layouts, and several other smaller projects. In addition, I completed a side project on plastic welding, where I gathered knowledge from online and internal resources and compiled guidelines for four common welding processes.

EGR 290 Coop Experience Summary

Major: Product Design and Manufacturing Engineering I was a mechanical engineering intern which meant I was heavily involved in the design aspect of the company. I designed a number of modifications for existing machines as well as parts in machines still undergoing preliminary design. I was also responsible for ordering parts for machines, updating designs, and updating drawings. I also had the opportunity to get involved with a local robotics team and designed a workstation for them.

Engineering Co-op at Emerald

Major: Product Design and Manufacturing Engineering During my first co-op semester I was able to design fixtures for multiple projects and was responsible for taking my ideas all the way through the design and manufacturing process. I became trained on the laser etching machines as well as the digital printer and used the machines frequently for different trials and engineering studies. I was able to obtain some experience with Emerald's quoting process as well to help supply accurate quotes to all of our customers. I was also able to be included in multiple DOE (Design of Experiments) studies to determine the root cause of some issues that arose and move forward with solving them.

Disher co-op Experience

Major: Product Design and Manufacturing Engineering As a co-op we all get a chance to show what we know and make the most of our experience. I started on smaller internal projects that improved Disher as a company. As time progressed I reached out and worked on developing a mechanized product for a company. Projects has a construction, solidWorks/design and electronics emphasis for me.

Royal Technologies - Plastic Injection Molding

Major: Product Design and Manufacturing Engineering The theme for my summer at Royal was "learn the company from the ground up". I accomplished this by learning a variety of positions. The coop started with me working as an operator and then quickly becoming a scanner/auditor. I was then moved to the utility position where I got to change molds on the injection presses and learn more about how the presses worked. A supervisor role brought more chances for troubleshooting issues and learning more about team management. Later I moved to assembly and assembly supervisor. Time studies and management were used to help maximize efficiency.

Read More About Royal Technologies - Plastic Injection Molding

Engineering Co-op

Major: Product Design and Manufacturing Engineering Tasks include print creation for sales and production purposes. Includes quality checking and some product development

Herman Miller Options Co-op II

Major: Product Design and Manufacturing Engineering In Herman Miller Options Engineering Department, I would engineer a customer's special order that had some deviations from the standard office furniture product. I would choose which products I wanted and had the ability to complete and start researching the standard products and the changes that were quoted. Then, I would create the appropriate CAD parts and drawings that were needed. The bill of materials would be altered by creating new parts, adding existing parts, and/or removing parts in order to match the order. I would self check all of my work, then pass it onto another engineer to audit. My product would then be signed off and sent to the next step towards manufacturing.

Landscape Forms Co-op Experience

Major: Product Design and Manufacturing Engineering For my co-op, I worked on updating work instructions for lines of product that were changed in any way. This included but was not limited to a fixture change or update, and update to hardware or an update to components. Also, I was able to do time studies of products to determine the correct time to allow to build each product. Finally, I worked with manufacturing and the shop floor to design and implement new fixtures

One World, One Dura

Major: Product Design and Manufacturing Engineering Disassembled competitor assemblies to perform competitive analyses and completed PowerPoint presentations with pictures to show the specifics of the competitor's shifter. Wrote VBA programs to pull specific data from a directory full of excel files and performed statistical analyses on the data. Worked with international engineers to get engineering drawings created using proper GD&T for parts and made corrections where needed. Made engineering changes to assemblies when component suppliers went out of business or discontinued parts. Designed and machined testing fixture to perform testing on manufactured parts.

Irwin Seating, 3rd Co-op

Major: Product Design and Manufacturing Engineering A big project I worked on was designing a new style of armrest from sheet metal which the customer would interpret as more expensive and classier. This project was tied into another one involving hybrid standard which results in cost reduction, and a new wood bottom style seat. Irwin Seating is known for doing a lot of custom solutions for customers that other companies might not, so I also worked on prototyping solutions for project bids. I also acted as support for other engineers' projects doing CAD and drawing work for them.

NASA Internship with Systems Integration and Test Branch

Major: Product Design and Manufacturing Engineering While working at Langley I was expected to complete a major project. This project focused on collecting information related to the design, assembly/integration, and launching of a small satellite. The goal eventually resulting in an accessible webpage that can be easily updates with new information. This was just the beginning of this project and there is still a lot that needs to be done. I also had the opportunity to witness and participate in a scientific balloon launch. I helped with document organization, hardware and ground support equipment packing before the launch. Once at the launch site I participated in launch day activities and data collection. The last responsibility that I had was to support the Thermal Vacuum Lab within the Systems Integration and Test Branch. This required me to write and run a Thermal Vacuum Test for space bound hardware, construct operational procedures for hardware, and help out where ever I could.

Read More About NASA Internship with Systems Integration and Test Branch

Summer 2015 Engineering Co-op

Major: Product Design and Manufacturing Engineering During the summer I was part of a five man cell that operates an automated assembly machine that produces electrical parts for Haworth office furniture. Daily tasks for the cell included being machine responsible to make sure the machine is running smoothly, daily machine maintenance, machine repair, and design for new machine processes or re-design existing processes. I spent a lot of time working on projects to improve the efficiency of the assembly machine that I worked on as well as a quality check station re-design for another machine in my building.

Koops Co-op

Major: Product Design and Manufacturing Engineering I did various controls work on several different machines such as PLC, HMI, vision camera and robot programming. Some of the projects I was involved in produced interior car panels, headliners, as well as other automotive interior components. My work lead me on multiple trips to Louisville, KY for install and support of a line I worked on, which was a great experience with the manufacturing industry.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.