Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Co-op Rotation 1

Collin

Major: Electrical Engineering

The work was very software focused with most hardware work being more basic, systems level analysis. I worked on creating new test engineering software packages as well as assisting in updates to existing software. However, the nature of what the software was being written for still necessitated an understanding of electrical engineering concepts.

Great Place to Grow

Logan

Major: Electrical Engineering

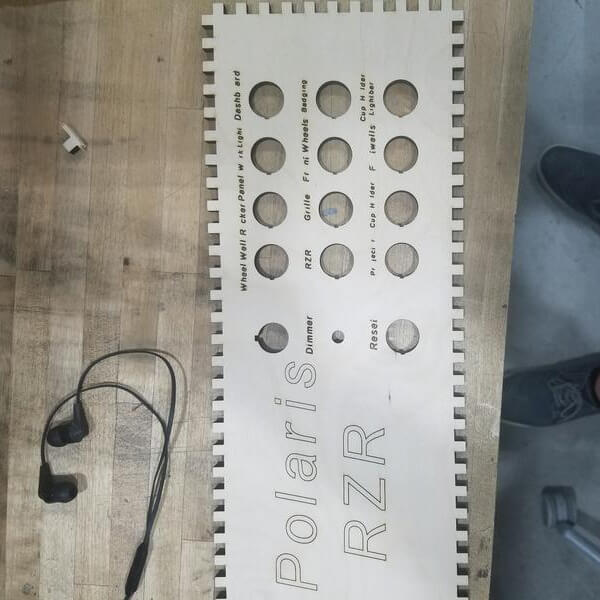

Quality control projects for production lines. Improvements in the production efficiency. Prototyping for off-road vehicle lighting.

Controls Engineering Co-op

Collin

Major: Electrical Engineering

My day to day activities included designing system layouts of control devices necessary to the operation of the system, drawing these systems in AutoCAD, and the documentation to support these installations. Once the system design and schematics are complete, the software has to be written for the programmable logic controller so it can correctly processes the input and output devices previously added.

Gateway to learning Electronics

Brad

Major: Electrical Engineering

The electronics lab was responsible for a large portion of the testing equipment used on the production floor. The most popular testing unit is known as the "lunch box" these are small boxes that allow the user to power a tail lamp and test the functionality of each lamp. Each of the boxes are built for a specific model of lamp, meaning that there are hundreds scattered around the plant. I was given the task to build these as well as maintain them when they broke. I also build more advanced testing units known as "smart lamps" these lamps allowed for individual LED control and were programmed with a micro controller. Throughout this rotation I specifically worked on the Ford Edge and the Ford Mustang.

Co-Op at Johnson Controls

Dan

Major: Electrical Engineering

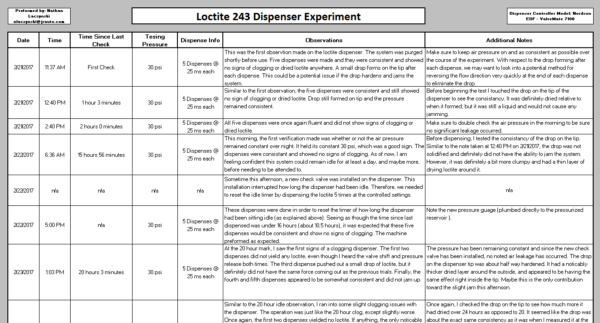

I am responsible for process development. I completed electrical schematics for a conveyor oven and developed a laser weld for hermetic sealing of lithium ion cells.

EGR 290

David

Major: Electrical Engineering

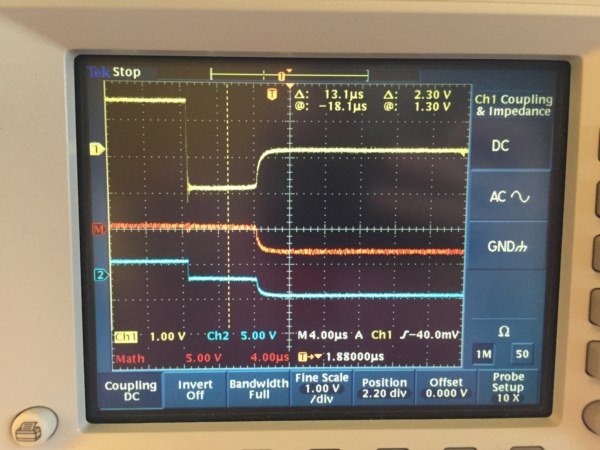

I was assigned a main project to work on throughout the co-op. This project had me design a peak current meter that was capable of measuring the peak on time current as well as continuous current of all types of industrial LED driver products. The meter was capable of measuring a wide range of current. I also worked on many smaller projects that allowed me to get experience with a variety of products.

2nd Semester Co-op

Karla

Major: Electrical Engineering

Mainly, I worked on maintaining and writing tests for a Hardware in the loop test system. I also performed manual tests, tech work in the lab, and rf antenna testing.

Co-op II

Joseph

Major: Electrical Engineering

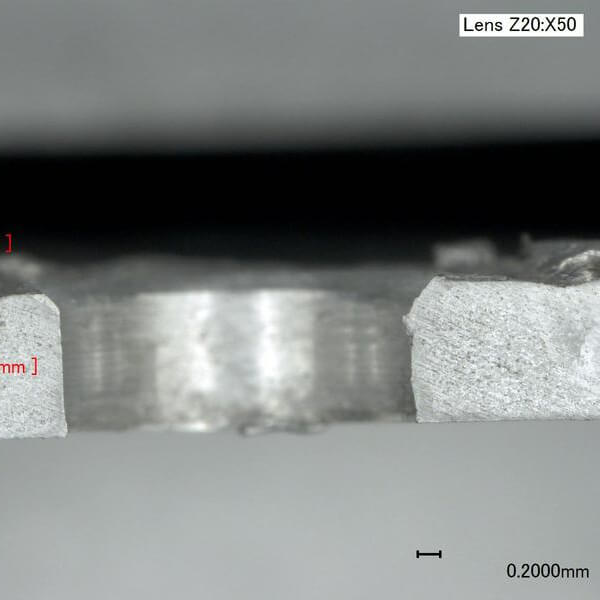

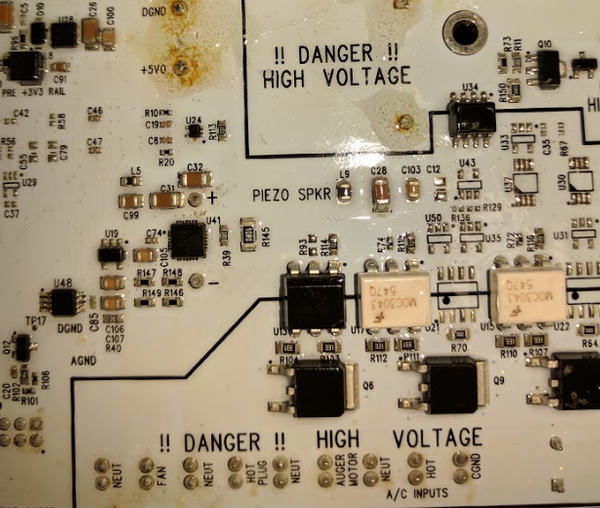

I assisted in the plant electronics lab, doing what ever needed to be done at the given moment. I repaired and built mobile product test unit for our production floor and customers (shown in the experience submission picture). I performed ESD testing to help design a board layout change. I developed test masters for the end of the line test stations. I also conducted failure analysis of warranty returned parts as well as managed some maintenance improvements in the lab itself.

Gaining Automation Experience

Matthew

Major: Electrical Engineering

Throughout this second co-op rotation, I was tasked with many new responsibilities that I didn't get to do on my first rotation. These responsibilities included designing and implementing a Human Machine Interface (HMI), establishing communication to the machine's components via various communication protocols, setting up the machine's diagnostic settings, and programming the machine. I was also involved enough in a project to leave the plant and help out with the installation and debug process on the customer site.

EMC Co-op Second Rotation

Daniel

Major: Electrical Engineering

During the second rotation of the co-op, I worked with clients to run a variety of test such as Radiated Emissions (RE), Conducted Emissions (CE), Bulk Current Injection (BCI), Radiated Immunity (RI), and Electrostatic Discharge (ESD). Compared to the first rotation, I was a lot more independent working with client's to perform these tests. I also worked on the diagnostic aspect of the products to understand how the product circuitry was producing failures and how to reduce these failures.

JR Automation 2nd Rotation

Nathan

Major: Electrical Engineering

For the first few weeks, I was placed on a project to get a repeat job's fixture up and running given the PLC and HMI. This was a great refresher and got me back into the controls engineering mindset.

Next, I spent a little over a month on a much larger project with various tooling fixtures. This taught me a great deal about the hardware implementation of several devices, while building my PLC and HMI programming abilities.

Finally, for the last two months, I have been doing a lot of design work. This included designing electrical and pneumatic prints for various jobs. I learned an outstanding amount about the automation process, as well as electrical and pneumatic functionality.

EBW Electronics Co-op III

Bryan

Major: Electrical Engineering

I did the PCB layout for a new product and put together all of the necessary design documentation. I also worked on creating thermal models of PCBs, so that the circuits hot spots can be predicted before prototypes are made. A couple other projects that I spent time on were working with an in-circuit programmer and helping with EMC testing.

MotorGuide Electrical Engineering Co-op

John

Major: Electrical Engineering

I validated product changes throughout the semester. From component level analysis to software changes, I made sure the final assembly worked properly as optimizations were made.

Hard Work Pays

Josiah

Major: Electrical Engineering

Sadly the project that I worked on this semester is confidential. I can only say that during this semester I worked with AC Phase control using microcontrollers, wiring harnesses and signal control. This project was one of the most difficult that I have ever worked on and I was lucky to learn so much!

third co-op rotation at Dornerworks

Aaron

Major: Electrical Engineering

I tuned a PID control loop for an embedded system. I documented the progress that I made. I changed a Python GUI for a customer.

Electrical Engineering - Hardware

Joshua

Major: Electrical Engineering

My job was to aide in designing circuits to be used for production or to support production.

Summer Co-op 1

Adam

Major: Electrical Engineering

Over the semester, I was given multiple tasks. One job I was tasked with was setting up a camera attempting to detect a bead of silicone. On the same job I was also tasked with designing seven different HMI (Human Machine Interface) screens. This task of setting up the HMI screens introduced me to PLC, as well as several pneumatic and electrical drawings.

Trane - EGR 290

Mike

Major: Electrical Engineering

I created custom graphics for the user's interfaces. The graphics are used by the customers to monitor their HVAC systems. I was also responsible for checking in the parts that had been ordered for different projects.

Consumers Energy Low Voltage Distribution Co-op

Tyler

Major: Electrical Engineering

Projects assigned to me ranged from electric distribution line planning, concepts and designs.

Tasks required for these projects included many detailed drawings, creative designs, technical calculations and accurate cost estimates. Other tasks required customer communication, and coordination with electric construction operations.

In addition, I had the opportunity to tour many different Consumers Energy facilites that introduced me to other company operations such as the Webber Dam Hydro Plant, Ludington Pumped Storage, and J.H. Campbell Coal Plant.

Read More About Consumers Energy Low Voltage Distribution Co-op

Experience at TwistHDM

Kyle

Major: Electrical Engineering

Validation for a new generation of our controls circuit involved a large amount of electronics testing equipment under temperature extremes, voltage surges, and many other "what-if" situations to ensure the product is bullet-proof. This also included fine-tuning of component values and the code accompanying it, applying external modifications, and actively looking for issues and addressing them as we go.

RF signal analysis using spin-testing in various configurations.

Root-cause analysis of components that failed in the field and working with manufacturing to address the problems.

Analysis of sensor effectiveness in various climates using Python scripts to interface with data sent from our controllers.

Supporting the engineers: applied many intricate mods to boards which involved cutting & re-routing PCB traces and replacing small surface-mount components.

Dornerworks First Rotation Co-op

Kevin

Major: Electrical Engineering

I was taken in as a hardware engineer co-op and thus all my tasks were hardware focused. I was task with making most of the board modifications for the lead engineers on the project team. I was also put in charge of functionality and performance testing of the many different circuits located on the customers PCB. This involved obtaining and setting up software to control specific signals and verify that the circuit functions as expected on both an analog and digital level. Also, I had to introduce the boards to worst case scenario options and verify that the designs did not fail. If the designs did fail it was my responsibility to help diagnose the failure and verify the the correct changes were made in consultation with the lead engineer. I spent most of my time in the lab working with oscilloscopes, DMM, and other electronic tools during the verification. I was also put in charge of the mechanical testing of the design in which the PCB boards would be enclosed in. This project involved exposure with the external customer and other engineering companies.

Summer Co-op

Chris

Major: Electrical Engineering

I worked with the office group to help design prototypes, repair and maintain part testers for the production floor, worked with Altium to design schematics and board layouts. I also made testers for ITW so they could test some of the boards we sent them. Along with working with the office group I also helped out the production floor with creating test fixtures and programming and testing parts.

Electrical Engineering Co-op 1

Nicholas

Major: Electrical Engineering

Most of the tasks and projects that were completed included C programming, hardware testing, and the interaction between software and hardware. Test engineering is important for keeping manufacturing error to a minimum.

Working as a contractor

Josiah

Major: Electrical Engineering

This semester was split into two halves. The first half had me working at Disher on small customer or stewardship projects. I also spent time during this semester learning the coding language of Python. The second half of the semester I spent working as a contractor for one of Disher's clients as a components engineer. I helped the client's components engineer transition the company to a new database software and check their old database for errors.

Largest and Great Company LG

Yoonsun

Major: Electrical Engineering

About work experiences, LG Chemicals are dealing with lots of automation devices. I learned process of battery production. Electrically, I was also dealing with lots of automation program. I was not actually designed a program. However, I had experiences with finding a problem on PLC Program.

Because I can speak Korean, I also worked with Korean technician. And then, I educated other engineers, operators and American technician.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.