Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Working in the world of EMC

brittany

Major: Electrical Engineering

I did a variety of tasks, some were day to day tasks which include several types of testing such as radiated/conducted emissions and radiated/conducted immunity. These tests would include working with customers, modifying products, and assessing data. Other tasks completed were long term projects that benefited the efficiency of the lab such as generated lab reports and creating profiles for testing standards.

Herman Miller 2018 Summer

Andrew

Major: Electrical Engineering

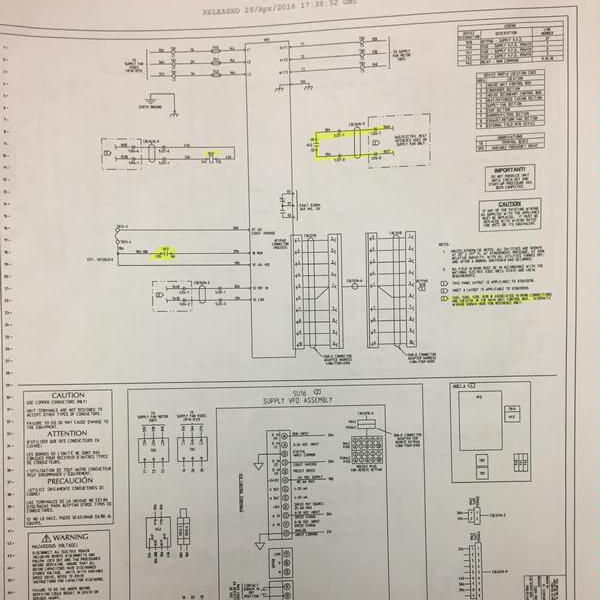

Throughout the summer, I've been introduced to a few different types of work at Herman Miller, Spring Lake location. Early on, I started with basic PLC programming using Rockwell software's RSLogix 500. There were a few simple assignments such as mimicking a stoplight sequence and taking the positions of analog sensors. As the summer progressed, my work team lead began assigning me work orders that consisted of issues throughout production. Many of these issues were caused in the PLC programming, whether it be timers that weren't correct, or certain limits that needed to be changed. The most exciting portion of updating the PLC programs is that everything was done online with the controller, so the machines and assembly lines were still running while the changes were being made. Most of the assembly lines and machines are programmed using RSLogix 5000, which is an expansion of RSLogix 500 and offers more functionality to a programmer. Later on in the summer I began working with the HMIs(Human Machine Interface) which are the main interaction between the line workers and the assembly lines. We try to design and program them as simple as possible, while making sure they have maximum functionality. Towards the end of the summer, I started working more with AutoCAD electrical for designing controller layouts and schematics containing sensors, switches, and other components. Along with the wiring schematics, I designed a few control panel enclosures that were later installed for a temporary project on a couple of the smaller assembly lines. The rest of the time this summer was spent working with my project team on the summer intern project. Every intern is placed into a group with 7 or 8 other interns and given a real company issue and the team is to present their solution at the end of the summer in front of the project sponsor, CEO, and many other employees.

Stepping Into The World of Industry

Edward

Major: Electrical Engineering

I was able to design and implement a Heijunka Kanban system for our electronics room. It will help the overall flow of the room and over time help increase the capacity of the room as WIP (Work In Progress) is reduced.

Foundation- Rotation I

Taylor

Major: Electrical Engineering

During my time at Gentex, I was able to work directly on the production floor as a part of a glass fabrication team. Some of my daily responsibilities consisted of servicing quality alarms, helping lead a team, and troubleshooting various issues. I was a member of a team focused on finding the root cause and permanent fix of a quality defect in our product. This consisted of extensive isolation testing, data management, and creating an innovative solution. Throughout my first co-op semester I was also involved in many small continuous improvement projects.

Co-Op 2

Jacob

Major: Electrical Engineering

I worked in the Mechanical Engineering department. I spent my time creating parts, assemblies, and drawings in Solidworks. I often created or modified individual parts for existing machines, but on several occasions I designed groups of parts for larger changes. On some occasions I worked on internal development projects.

Controls Co-Op (Round 2)

James

Major: Electrical Engineering

I worked on the controls side of a R&D storage machine as well as a semi-automated assembly line for a major manufacturer.

Small Company, Lots of Experience

Joseph

Major: Electrical Engineering

I usually ran different tests on various products. I maintained lab cleanliness and submitted test reports to the customers. I also typically greeted many customers in the morning and helped them get set up for tests while the rest of the company came to run the tests.

Test Engineering Co/op

Thomas

Major: Electrical Engineering

I ran many tests on specific units and designed new testing processes and software for specific units. Alongside this I worked on developing hardware for a station to run tests on units which involved circuit design and software design.

Test Engineering Co-op: Rotation 2

Collin

Major: Electrical Engineering

I worked in test engineering so I helped support and automate the test engineering processes. Almost all of our products must be vetted before leaving the facility so that was the job I assisted in. There was coding, computer support, and mild schematic analysis involved.

Controls Engineering Co-op Experience with ArtiFlex Manufacturing

Kyler

Major: Electrical Engineering

My day-to-day tasks consisted of hardware and software design for various machines. Projects that I was involved with included a laser marking machine, a seat riv-nut insert machine, and a robot spot welding cell. I completed a few programs and electrical schematic drawings along with standard documentation for various machines.

Read More About Controls Engineering Co-op Experience with ArtiFlex Manufacturing

Dematic Co-op II

Collin

Major: Electrical Engineering

Controls Engineering at Dematic consists of determining type and location of various controls devices needed to transport product through a system of conveyors, sorters, and storage systems. It also includes designing the control cabinet. The cabinet contains the switching devices to control motors, as well as the main control device such as a programmable logic controller. It provides power distribution to all conveyor and devices under its control.

Audio/IT Test

John

Major: Electrical Engineering

My co-op focused in two areas: Test Bench Creation & Assisting in Vehicle Tests. Most of my time was spent designing and creating a test bench area that is meant to seamlessly simulate a vehicle's Audio/Infotainment functions (Meter, Head unit, navigation, USB Port, Radio, SXM, etc). By using the test bench, the engineers can perform all software tests without getting into an entire car. Thus saving time and the number of reserved vehicles for the department.

I collaborated with other engineers to design & build a mechanical frame to place all of the equipment. Then, documented/constructed all of the electrical wiring & harnesses that connects each device together to form a complete system.

On another note, each week I acted as an assistant for my co-workers in performing various vehicle tests such as GPS Synchronization, USB Performance, etc.

JR Automation Co-op 2

Natalie

Major: Electrical Engineering

I spent time this semester doing a few different things. The first thing I worked on was making red-line changes to electrical and pneumatic prints. Next, I set up a vision system to be able to take a picture of a completed part and determine whether is was good or bad. After that, I was placed on a project team and got the opportunity to assist in the PLC programming and creation of HMI screens for a new project. I also spent a little bit of time teaching points to robots.

Co-Op I

Michael

Major: Electrical Engineering

Tasks include supporting the product manufacturing team with Work Instructions, updating Bill of Materials, and releasing Engineering Change Notices. Projects include creating Testing Fixtures that ensure all of our shipped products meet specification.

Electrical Engineering Third Rotation

Chris

Major: Electrical Engineering

During this semester I was able to work on multiple projects. I was assigned the task of designing and fabrication an end of line for our production line. This project involved a circuit layout, Linux and C coding, and mounting and fabrication of the enclosure. I was also able to design and work on multiple different products for out customers.

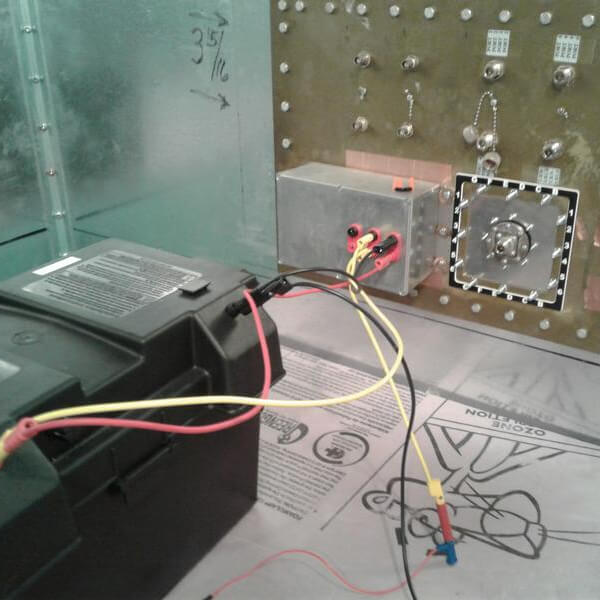

Co-op 3

Nicholas

Major: Electrical Engineering

I was part of the daily tasks that would help keep production running smoothly while also being part of the bigger projects associated with testing. I specifically was in charge of designing a brand new test station that was to be used in the testing of batteries before a product is shipped out. The process in creating such a station included both hardware elements and software elements that taught me a variety of skills.

EMC Co-op Third Rotation

Daniel

Major: Electrical Engineering

During the third rotation of the co-op, I worked with clients to run a variety of test such as Radiated Emissions (RE), Conducted Emissions (CE), Bulk Current Injection (BCI), Radiated Immunity (RI), and Electrostatic Discharge (ESD). Compared to the prior rotations, I was a lot more independent working with client's to perform these tests. I also worked on the diagnostic aspect of the products to understand how the product circuitry was producing failures and how to reduce these failures (debugging).

Third Co-op Rotation

Matthew

Major: Electrical Engineering

This is my third and final co-op rotation at JR and it has definitely been the best one so far. I've had the opportunity to be very hands with the machines I've worked on. I've been able to design the electrical systems, program the machines, work with robots, design the operator touch screen layouts, troubleshoot wiring and pneumatic issues, attend meetings with the customers, and travel to the customers location for machine installation.

3rd co-op rotation

Nathan

Major: Electrical Engineering

My role included various PLC and HMI programming tasks, the control of varying frequency drives, servo motors, conveyors, and various other pneumatic/electrical jobs.

1st Co-Op at JR Automation

James

Major: Electrical Engineering

Over the course of my co-op rotation, I completed a good deal of programming in both HMI (Touchscreen) and PLC (Ladder Logic) formats. I also helped troubleshoot issues with electrical, pneumatic, and mechanical problems on various projects at my business unit.

Automation Design

Joseph

Major: Electrical Engineering

While working at Koops I got to experience first hand the design process of creating automation systems. Some of the projects I was assigned during my time at Koops was working side by side with other engineers to design automated systems. Another project I was assigned to was updating older automated machines. All of these task contained a great deal of engineering work such as design analysis, technical drawings, stress and strain analysis, and etc.

Controls Engineering in Automation

Kyler

Major: Electrical Engineering

After working with AutoMatrix for the summer I was able to design, wire, program, and troubleshoot various machines in the automotive industry. AutoMatrix focuses on automating processes that help other businesses improve efficiency and productivity. Although they are a smaller company, they take on some very large projects for very reputable companies. My co-op experience consisted of programming a machine that loaded magnets into a rear-view mirror holder for a new electric car company. I also designed and programmed a laser marking system for the same company. The machine was responsible for providing a VIN number and logo on both front and rear bumpers.

Twisthink Co-op Part 1

Christopher

Major: Electrical Engineering

During this semester I worked on vision system projects, test setups, Wi-Fi pattern testing, board modifications and component tests. Since Twisthink is a consulting firm, it gave me the opportunity to work on a variety of different projects for a variety of companies. For the vision system projects I ran tests with multiple camera captures and wrote a variety of MATLAB scripts to analyze the results and modify the images. This also involved a lot of data formatting and developing file structures. For the test setups I build and evaluated setups for Wi-Fi pattern testing and fluid water sensing. I also did a lot of Wi-Fi pattern testing to determine the best locations for Wi-Fi board and external antennas on appliances. This involved mass data collection, data analysis, board programming and board modifications. Over the course of the semester I assisted in the rebuilding and redesign of the test platform that we currently used for Wi-Fi testing. Finally I did a lot of board modifications that included working under the microscope to change resistors, rewiring board and making a variety of harnesses.

Testing ,Testing, 123

Tom

Major: Electrical Engineering

My work at L3 was focused on Test Engineering and the rigorous testing process which aviation products have to go through. Software work was emphasized as much of the mechanical/ electrical aspect of the design is taken care of by the initial engineering team as the products are designed. Work towards a "station test box, test" was the bulk of the work done during the co/op. This involved building intricate knowledge of the circuits and signals involved in the testing of a set of products as well as working with software to send and receive specific in order to check their validity.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.