Co-op II: Innotec Group

Experience Information

Employer: Innotec Group

Job Title: Co-op

Major: Electrical Engineering

Received Credit: Yes

Paid: Yes

Abroad: No

Description of the Organization

Innotec is an innovative company made up of a majority of engineers, who design creative products and processes. The organizational structure is unlike any other business, since all employees are business owners who work in small units called cells that design, build, and manufacture automated solutions. Innotec has bases on four different continents, and has around 165 US employees.

Description of the Tasks/Projects Completed

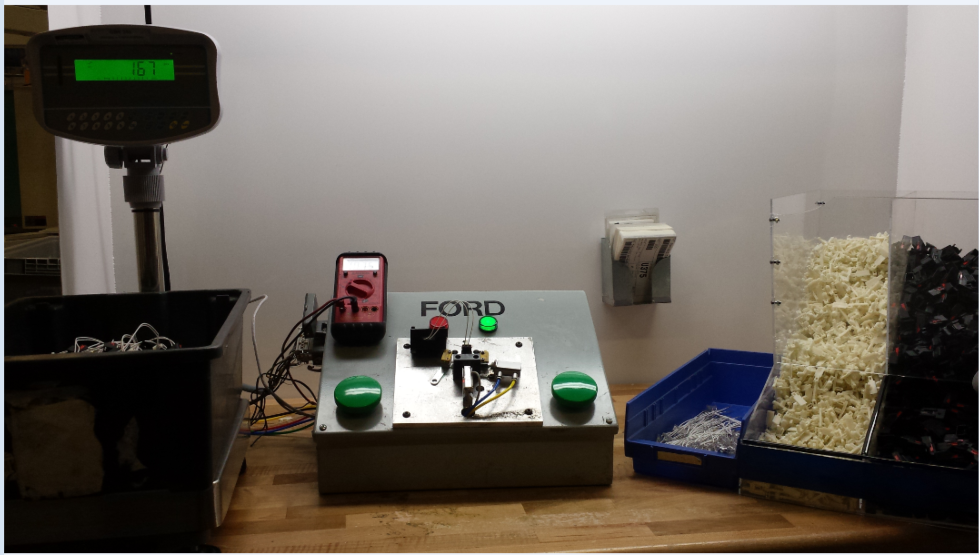

In terms of electrical projects, I completed a limit switch project, thermolator project, planned a large controls project, and learned about extensive relay logic. With these projects I learned new 2D CAD software, how to properly draw my own electrical wiring diagrams from scratch, how to work with relays, how to use auxiliary contacts, and much more. I also worked on putting together on-line electrical-check stations for some of the products that my team produces, fixed countless wire and connector damage, updated sensors, and x-rayed parts to help understand electrical failures. Mechanically, I learned how to operate a manual three-axis mill,successfully milling limit switch stops, an entirely new electronic-check station for one of our products with over ten detailed parts needed, and color check stations. Additionally, this semester I assisted our launch team. I made over a dozen unique prototypes for a new product on a CNC machine, which required learning a new CAM software and a new milling interface. I measured light intensity and color data for thousands of parts for multiple new products. I also helped perform analysis on diode functions and analyzed multiple different design performances to choose which scheme should be kept for a final product launch. There were so many more amazing experiences that I worked on, from presenting at company meetings, attending design reviews, ordering materials [working with supply chain], to assisting with 5S projects. I learned something new every single day at work, and I highly recommend Innotec to anyone who wants a fast-paced, hands-on job!

Skills/Knowledge Gained Through The Experience

The specific skills/knowledge I gained are below: "Manual Milling o Includes: set-up, speeds, basic material knowledge, angles, tool changes, etc. "Two-Sided CNC Machining o Includes: set-up (getting things square is very challenging until a system is put in place), feed rates, speeds, tool type and knowledge, finishing, cut paths, g-codes, etc. "Timed Relays "Light Intensity/Color Knowledge o Includes: measurements, bin knowledge, experimenting with color and intensity parameters to induce shifts "Limit Switches "DraftSight 2D CAD "Mach3 Software (for CNC machine) "MeshCAM "Advanced Soldering Skills "Cost Effective Ordering "Molding designs o Castle walls, gatings, basic mold flow, basic circuit design for support "Advanced Excel Skills "Mechanical Drawing Interpretation Skills "Presentation/Public Speaking Skills "Mechanical Knowledge o Bushings, Reamers, Rivets, Arbor Presses, Drill Presses, Band Saw, Dremel, Belt Sanders, etc.

Favorite Part of the Experience

My favorite part of this co-op rotation was the variety of new experiences. At first I wasn't that excited about spending a large portion of my time on mechanical projects, but I realized that they are super fun and extremely applicable to my future career. I also liked analyzing products and working towards a finished product. I enjoyed gaining skills in all areas of engineering, not just electrical, while still maintaining a strong electrical focus.

How the Experience Influenced Future Career Goals

This experience has reaffirmed my choice to major in Electrical Engineering and minor in Computer Engineering. I have a large interest in going into a manufacturing/automotive field upon graduation thanks to this co-op.