Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Mechanical Engineering Co-op Rotation #1

Jacob

Major: Mechanical Engineering

As a mechanical engineer intern in their first rotation I took on design lead in several projects rather quickly. I was tasked with designing and creating models in SOLIDWORKS for several brackets, wall art, and linkage systems. Conducting prototyping with 3D printed parts after the models and drawings were complete. Created bills of materials for several projects. Also wrote design reports and pulled together presentations on project progress to share with the customers.

Magna Mirrors - 1st Rotation Co-Op

Jamal

Major: Mechanical Engineering

During my first rotation at Magna, I was tasked with measuring and analyzing critical dimensions on mirrors, conducting capability studies on various processes throughout the facility, programming a multisensor measurement system, and creating MRO forms for spare parts. I also had the opportunity to do some design work in SolidWorks for multiple new machine components.

Aerospace Co-op Experience

Dawson

Major: Mechanical Engineering

This summer I was able to work in Commercial Shroud components, which are directly installed into commercial jet engines for Boeing and Airbus planes. My goal this summer was to implement control limits to 30+ product families, and see out that these were restricting tolerances to ensure better parts and more confidence.

Engineering Intern

Micah

Major: Mechanical Engineering

Since it was my first co-op rotation at Trans-Matic, I worked mostly on revision work. Revision work involves updating engineering drawings to match changes in the tooling or layout changes made by the toolmaker. However, as the rotation progressed and I gained more designing skills, I was assigned projects that required design work to fulfill requests made by the toolmakers or customers. For example, one of the toolmakers wanted some grating dropped eighteen inches in Trans-Maticýs large 240 press. Although it sounds like a relatively easy task, it was challenging since the grating still had to fit in the confined space provided while following regulations mandated by OSHA. In short, as I gained experience at Trans-Matic, I received projects that tested my abilities while also allowing me to gain new skills.

Shaping Metal, and a Career

Nathaniel

Major: Mechanical Engineering

As an Engineering Intern, the majority of my tasks involved part/drawing/print updates and the use of Creo (Pro-E), my new favorite CAD software. Tool-makers on the shop floor would make changes to prints in order to improve tooling and the quality of production parts; it was my job to verify and implement them. I was also given a handful of small projects that involved developing creative solutions to real problems. I enjoyed these a lot, as I was able to exercise some creativity and apply concepts from previous coursework.

First EGR Co-op Semester

Samuel

Major: Mechanical Engineering

This semester I completed a lot of interesting tasks and assignments. One task that was commonly assigned to me was completing engineering change requests. These are usually changes in dimensions or part numbers in a certain table/desk assembly that requires me to go through and change all of the engineering drawings that contain the part that was changed. Along with this, I also created setup drawings where I would have to add all of the different parts in a desk assembly and then create the engineering drawing for it. One project I did this semester was created nested drawer CAD files and then worked with a CNC programmer to mill out many drawer panels out of sheets of melamine. Another project I completed was designing a new modesty bracket for a table. I had to redesign the hinge to be universal because it had been assembled wrong on some tables and caused the veneer to tear off the modesty panels.

Magna Co-op

Lucas

Major: Mechanical Engineering

At Magna engineering I worked on projects that provided product support to validation testing, manufacturing, product development, and customer relations.

Engineering Co-op #1

Mallory

Major: Mechanical Engineering

My first rotation of co-op consisted of an abundance of different tasks. I assisted in an engineering transfer, where I completed the required testing/reporting. I completed process, operational, and installation protocols as needed for both the engineering transfer and regular operation. I helped work the backroom of an audit, participated in customer meetings and projects, and wrote, updated and revised documentation as needed.

Realization that it is worth it

Marshall

Major: Mechanical Engineering

My tasks can be broken up into daily responsibilities, large projects, and odd jobs. My daily responsibilities include running APDýs 3D printers. We have a very large FDM machine and two SLA printers. It is my job to ensure any requested prints be completed on time and the requestor receives regular updates on their parts. If a print was requested from outside of APD, I would have to walk them through the resin selection process and explain the finer details of 3D printing if they had any questions. Many of the large projects I worked on I cannot explain due to my NDA, but let it suffice that during my rotation I completed testing, which included hands on measurements and method creation, data analysis, and data/ result presentations. Through my work on the larger projects, I have gained a new appreciation and understanding of proper methodology and data recording, along with how to create professional yet enjoyable presentations. Many of my odd jobs included normal intern stereotypes. Scheduling appointments, contacting dealerships, coordinating teams, and designing tools for the office (printed on our 3D printers of course) were all tasks that could be asked of me by any of the engineers within APD.

OSM Engineering Co Op

Benjamin

Major: Mechanical Engineering

Magna Mirrors includes a lot of testing of prototype materials and parts. There might be a large sum or a small amount due to how much prototypes are available for testing. The testing is simple to do but it might take once or twice to get used to get a hang of things. therefore, I recommend doing practice tests on parts that already have been tested to compare results with the concluded results to check accuracy and precision.

Summer 2021 Co-op experience

Jeremy

Major: Mechanical Engineering

I worked on many smaller physical projects and some larger ones. About 40% of my time was spent working on projects, and the rest of my time was spent running production on our assembly line. The projects were almost always geared towards improvements and updates to the line I worked on. One major project was assisting in moving an injection molding machine onto our line, which required many smaller projects like designing and building a feeder mounting plate, building machine doors, and plumbing hoses on the machine.

First Co-op Rotation at Rose Medical

Jenna

Major: Mechanical Engineering

My tasks at Rose Medical were split into two categories: process development and protocol writing. My main assignments relating to process development were to design 3D fixtures to aid in the manufacturing processes, run DOEs to determine which settings the product should be made in, and evaluate how successful a product is when certain conditions change. For protocol writing, I wrote numerous installation qualifications, operational qualifications, process qualifications, memos, and customer-requested validations. My task was to write the protocol, take the necessary data, and write a report for the customer. On top of product development and protocol writing, I was heavily exposed to the workings of a cleanroom environment, I was able to sit in on customer meetings and calls, and I learned about new technology and equipment.

First Co-op Rotation at Gentex Corporation

Ben

Major: Mechanical Engineering

During my co-op, I was responsible for several projects that sought to improve our manufacturing processes. Most of my projects involved designing fixtures to aid in the calibration processes of our machines. In addition, I also conducted preventative maintenance and efforts to improve assembly line ergonomics.

First Co-op Rotation

Olivia

Major: Mechanical Engineering

I was on a team that want confined space entries to be significantly reduced due to them being unsafe and very expensive. I worked on a mechanical arm that would be able to do the tasks that a human would normally do during these confined space entries. I was able to get feedback from the inspectors and then further improve the pole.

I oversaw an underground pipe inspection which was a lot of emails, calls, and meetings with lots of different companies.

I helped in the risk management software that Corteva has, which was exciting to use a new software.

Jr. Fire Systems Engineer

Daniel

Major: Mechanical Engineering

I designed fire sprinkler systems for various building types, ranging from residential to industrial.

Custom Automation Engineering Co-op

Camryn

Major: Mechanical Engineering

During the semester, I was mainly responsible for writing the ladder logic for PLCs as well as creating HMI screens for a couple different machines. I started out by completing small programming tasks to help my mentor complete a project he was working on. I was then responsible for programming two different machines on my own, with help from my mentor of course. After completing the programming of those machines, I worked with the customer to make any changes to the ladder logic or HMI screens in order to ensure the machine ran according to what they expected. I spent additional time helping my mentor with small tasks on a larger machine he was responsible for, such as figuring out how to set up new ethernet devices.

Co op Position at Hutchinson

Andrew

Major: Mechanical Engineering

I worked on failure analysis of durability parts and tested parts to meet specifications. I also visited companies that Hutchinson works with in outsourcing some tasks, like plastic over-molded brackets.

Interning at LG

Connor

Major: Mechanical Engineering

At LG I was put in charge of the crating process which sent material to another one of our factories. Also, I worked on safety improvements to some of the roll press machines to get rid of pinch points operators run into. Also I assisted on a project that used Tekscan software to use a pressure sensor to determine the wear of the roll press and the many sub rollers on the machine. Finally, I added adjustable feet to a table. This allowed for the Tesa measurement device to take more accurate measurements by leveling and stabilizing the table.

Hutchinson Co-op

Nick

Major: Mechanical Engineering

-Prototyping Lab production

--Testing and creation of Rubber parts to have the correct properties of the rubber/plastic

-Validation Lab

-- Testing of multiple parts for characterization and properties of the fluid in said parts

--Multi-directional ultimate testing

-GM Team

--Fixture Creation

--DFMEA creation

--Design improvement

--Development meetings

Integrated Packaging Machinery Co-op experience

Brody

Major: Mechanical Engineering

As a Co-op student at IPM, I did a lot of computer aided design in programs like Solidworks and AutoCad. I had the opportunity to work on real projects with sometimes very custom solutions and problems which I had to work through with members of the team. Overall, I felt as if I was a functional member of the engineering team at IPM and not just an intern.

Read More About Integrated Packaging Machinery Co-op experience

Magna Co-op

Zakary

Major: Mechanical Engineering

Throughout the course of a semester, I put to use my skills learned in classes to help improve on the design of a robot used for cycling. I was also able to help with determining how parts would fit together for a new mirror as well as complete multiple kinds of testing to determine if the mirrors were meeting required standards.

Axis Automation Second Co-op

Mason

Major: Mechanical Engineering

This semester I worked on a variety of projects on the back end of the design process. This consisted of detailing prints for parts and assemblies, redesigning and updating existing designs, verifying robot loads, and evaluating robot and fixture interaction.

Co-op Student at RDI - Semester 1

Andrew

Major: Mechanical Engineering

The first half of each day began by cleaning, inspecting, and organizing the pattern plates that were recently ran. During this time, various other tasks could come up including shipping out or receiving patterns, stamping unmarked patterns, and watching a sample run for a modified or new pattern.

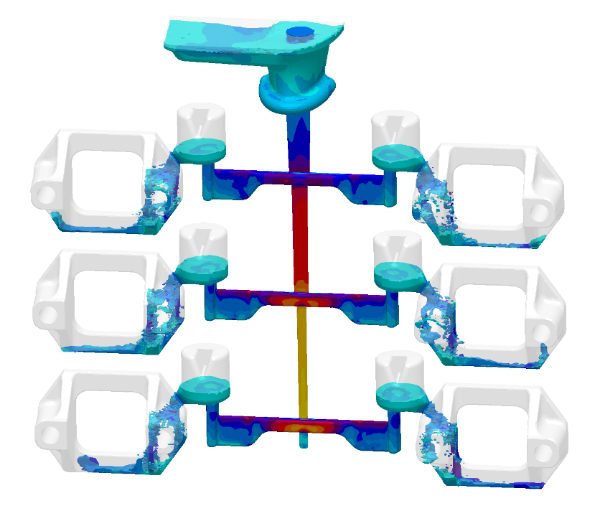

The second half of each day usually consisted of various jobs on the CAD program Creo. I reverse engineered patterns on transfer tools and created new tools from scratch. Molten iron flowing through the created patterns was simulated in a program called Magma. These simulations were then used to make modifications to potential new patterns as well as improvements to existing tools.

Magna Mirrors Co-op Experience

Joshua

Major: Mechanical Engineering

I did a variety of tasks. Much of my time was spent in preparation for engineering builds for prototypes, studies, etc. This required me to gather mirror components and arrange for time to be spent on the line. I also performed studies/gathered measurements. This usually came in the form of dimensional measurements, reflectivity measurements, angle measurements, and Instron measurements (pull-out strength, for example). I also had several longer term assignments, such as designing a portable "suitcase" tester for a new video mirror, and a role in producing, testing, and statistical analysis of mirrors built with experimental aluminum tubes (replacing steel).

Third Co-op Rotation

Jordyn

Major: Mechanical Engineering

I analyzed customer verbatim and complaints, benchmarked competitors, and made possible recommendations to improve customer satisfaction

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.