Sailing at 1/12th scale

Engineering tradition celebrates 25 years

by Leah Twilley

video by Jeremy Knickerbocker

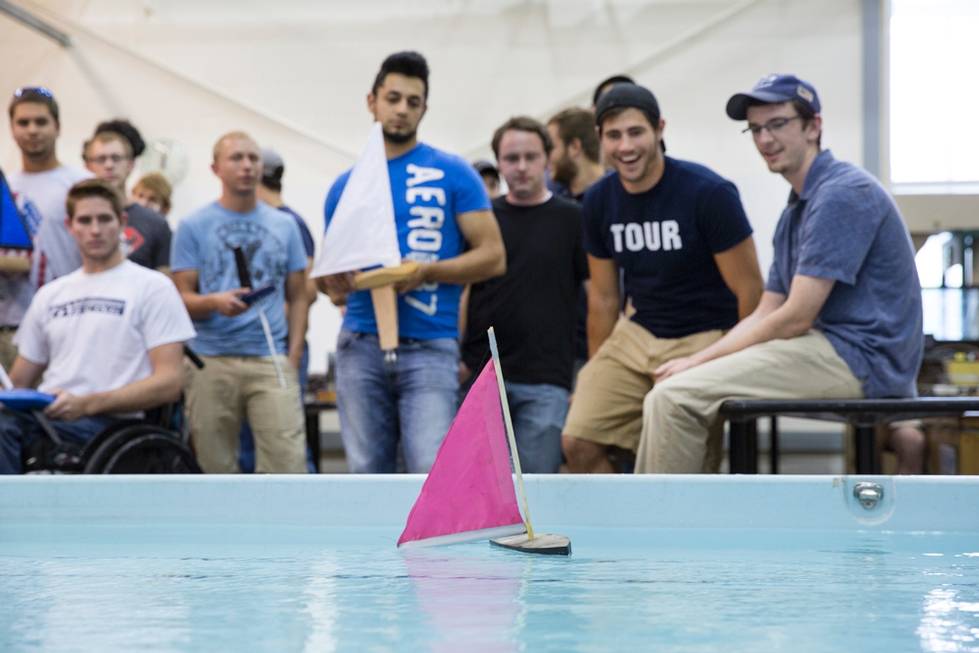

It was a race to the finish on the high seas in the Fred M. Keller Engineering Labs during the 25th annual Wooden Shoe Regatta in July.

Junior-level students majoring in mechanical engineering readied their handmade sailboats for style and speed competitions to celebrate the conclusion of a summer-long course about fluid mechanics.

Using principles of fluid mechanics, like buoyancy and stability, students applied lessons they learned in class to model sailboats they built throughout the spring and summer semesters.

Shirley Fleischmann, professor of engineering, began incorporating sailboats as a way to teach the course when she taught at the U.S. Naval Academy in Annapolis, Maryland, in the early 1980s.

A group of 66 students participated in this year's 25th annual Wooden Shoe Regatta in the Fred M. Keller Engineering Labs.

photo by Elizabeth Lienau

“I found that students weren’t enjoying the course, and I felt they should not only understand fluid mechanics, but also enjoy the subject, since they would spend a lot of time on ships,” Fleischmann said.

The idea to incorporate ships came to her while carving a small sailboat for her children.

“I remember thinking that I needed to find something to tie in all the material I was teaching in class, and I thought, ‘This is it. I’m holding it,’” she said.

It was a success among her students at the Naval Academy, so she taught fluid mechanics the same way when she joined Grand Valley in 1989. It has since become a tradition in the School of Engineering.

Students use a 2-inch by 4-inch by 10-inch block of basswood to construct the 1/12 scale model sailboats, complete with the important pieces of a sailboat: the hull, rudder, keel and sail. Throughout the semester, they conduct tests to predict how the full-scale version will operate, which Fleischmann said is the same process engineers have used for years.

“They do a lot of adjusting, which is good because they’re thinking about the sailboat as a system, which is what engineering is all about,” she said. “Students must think, ‘I’m building a system, there are forces on it, how can I control those forces?’ Whether it’s the Eiffel Tower, a car or a boat, the process is the same.”

At the end of the class, students submit a report of their tests and outcomes. Then they celebrate by showcasing their boats at the Wooden Shoe Regatta.

During the speed competition, students approach the 12-foot pool one at a time, place their sailboat in the water and release it. A line of fans at the edge of the pool serves as the wind tunnel and onlookers wait to see what happens. Most often the ship goes straight across, but the builder of the fastest boat is named the winner.

This year, the winner of the speed competition was Davis Moes, with a time of 4.67 seconds, and the winner of the style competition was Kyle Werner. Each winner receives a trophy — a wooden shoe from Holland, hand painted by Fleischmann.

The fluid mechanics class has grown from a class of 10 students in the early 1990s to a record group of 66 students this year.

Fleischmann estimated that about 750 students have constructed sailboats over the years, including Dave Nagy.

After receiving a bachelor’s degree in mechanical engineering in 2001, Nagy went on to earn a master’s degree in naval architecture from the University of Michigan.

Students watch a sailboat race to the finish line at this year's Wooden Shoe Regatta.

photo by Jess Weal

He currently serves as a ship design manager for the U.S. Navy in Washington, D.C., where he works in the office responsible for building and designing Virginia-class submarines, a class of nuclear-powered fast attack submarines. He oversees the design, construction and purchasing of all naval ships.

He said he learned a lot in Fleischmann’s fluid mechanics class because she emphasized both theory and application.

“I’ve always had an interest in designing ships, so the experience of building a boat nicely dovetailed into what I had been interested in for a while,” Nagy said.

The process of designing a submarine is a combination of all types of engineering, said Nagy, especially mechanical. The interior requires marine engineering, the hydraulic systems require mechanical, and the power plant requires nuclear engineering and electrical engineering.

He said that while his first sailboat design in Fleischmann’s class was not terribly successful, he learned a lot from doing it, which helped him succeed in graduate school.

“The second your boat hits the water your mind starts working and you think, ‘OK, I would change that, that and that,’” he said. “It was a very gratifying experience.”

Fleischmann helps a student prepare to launch her sailboat during a past regatta.

photo courtesy of Shirley Fleischmann

Engineering major Caitlyn Hurley, from Clinton Township, can relate. She said going from learning theory in the classroom to applying knowledge in the lab was really helpful.

“Building the sailboat and seeing it sail was fun, but the hardest part was collecting hull resistance data and analyzing that data to predict points of sail and how fast it would go if it was a full-size sailboat,” said Hurley.

At the very beginning of the 12-week class, Fleischmann recommends her students observe full-size sailboats. And the best place for that, she said, is along the shores of Lake Michigan.

“I always say to them, ‘Part of your assignment is to go down to the lake and observe the sailboats coming in and out of the channel. Look at where their mast is and what they look like under sail,’” she said. “They all have a pretty common design.”