Applied Medical Device Institute at GVSU awarded $500k grant for medical device manufacturing study

Grand Valley's applied Medical Device Institute (aMDI) has been awarded $500,000 by the Grand Rapids SmartZone to complete an investigation into the viability of using specialized 3D printing technology for medical device production.

The grant will allow aMDI, in collaboration with MediSurge and Carbon, Inc., to create production-grade medical devices that can be safely implanted into and under the skin, which isn't currently possible due to existing materials used for prototyping.

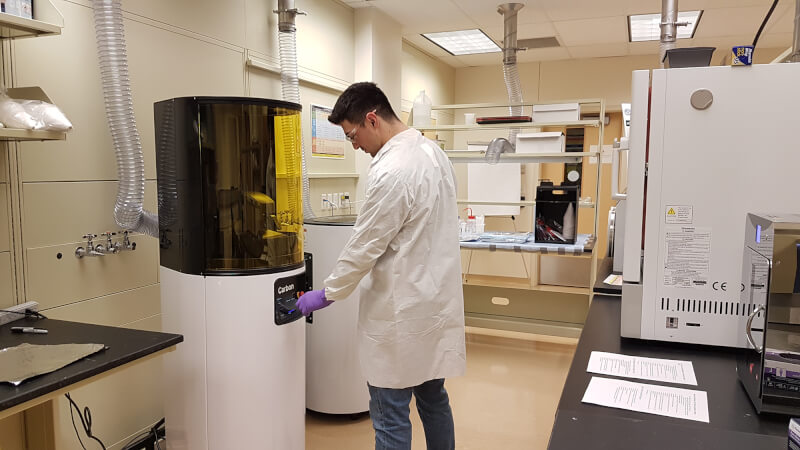

A brand-new, state-of-the-art Carbon, Inc. 3D printer technology has been installed in aMDI's incubator space in Grand Valley's Cook-DeVos Center for Health Sciences on the Health Campus, making Grand Valley the only university in the Midwest, and one of only six in the nation, to give students an opportunity to work with the revolutionary technology.

"We are thrilled to be the first university in the Midwest to provide students with direct access to this type of innovative technology on campus," said Brent Nowak, executive director of aMDI. "This novel 3D additive manufacturing technology, targeting medical grade materials, will soon be the new standard, and this study will be a launch pad for course content that is used in curriculum throughout the university."

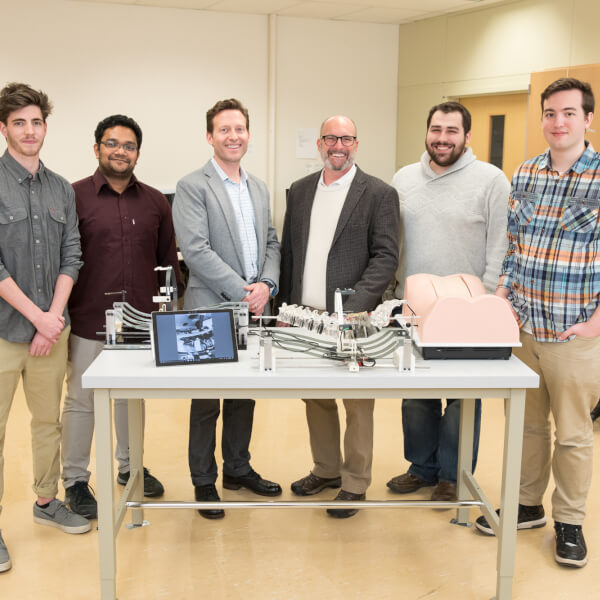

The grant also supports student learning and development, as more than a dozen graduate and undergraduate students from Grand Valley's Seymour and Esther Padnos College of Engineering and Computing, along with faculty, will have opportunities to engage with the aMDI team on research projects in a real-world laboratory and learning environment.

Nowak said he hopes the study also sheds light on ways to accelerate the process of device development as well as the manufacturing cycle.

Upon completion of the study and determining scalability for 3D printing of medical devices at production volumes, MediSurge would be the first medical device manufacturing company in the Midwest to offer this kind of service. MediSurge is also providing funding and engineering support to the study.

aMDI provides access to researchers, engineers, medical professionals, and business and entrepreneurial professionals. It uses an integrated approach that includes intellectual property, business review and mentoring. It was established in 2016.

Learn more at gvsu.edu/amdi.

Subscribe

Sign up and receive the latest Grand Valley headlines delivered to your email inbox each morning.