Two industrial 3D printers were installed in the Shape Corp. Innovation Design Center, giving Grand Valley students opportunities to learn additive manufacturing (AM) and collaborate with area industrial partners to design and build parts or prototypes.

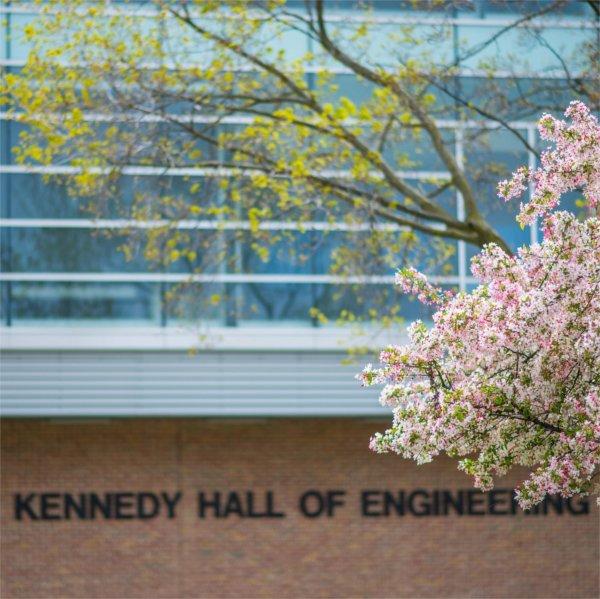

The new equipment also gives Grand Valley's applied Medical Device Institute (aMDI) a second location. A unit of the Padnos College of Engineering and Computing, aMDI has space in the Cook-DeVos Center for Health Sciences. Money to purchase the 3D printers and related equipment came from the $1 million in federal appropriations Grand Valley received last year to expand aMDI's capacity to better serve clients.

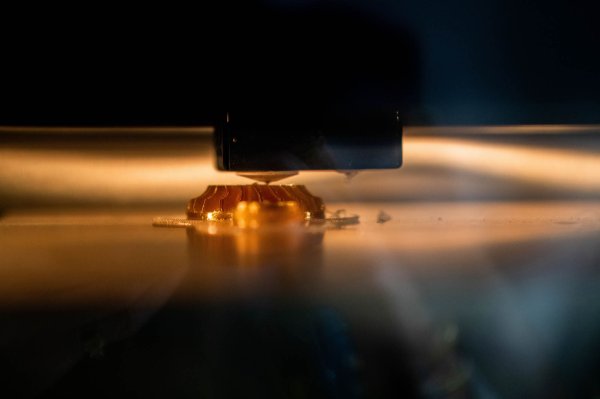

Brent Nowak, executive director of aMDI, said the 3DXTech printer, GearBox, is from a Grand Rapids company and provides a "unique open platform that allows our faculty and students to explore, investigate and research the boundaries of science and engineering."

The Markforged MetalX printer uses a wide range of metals from stainless steel to copper, which Nowak said is a first for GVSU.