Faculty artists use university 3D printers to help create face shields for health care workers

Two Department of Visual and Media Arts faculty members are creating face shields for health care workers, primarily through the use of departmental 3D printers.

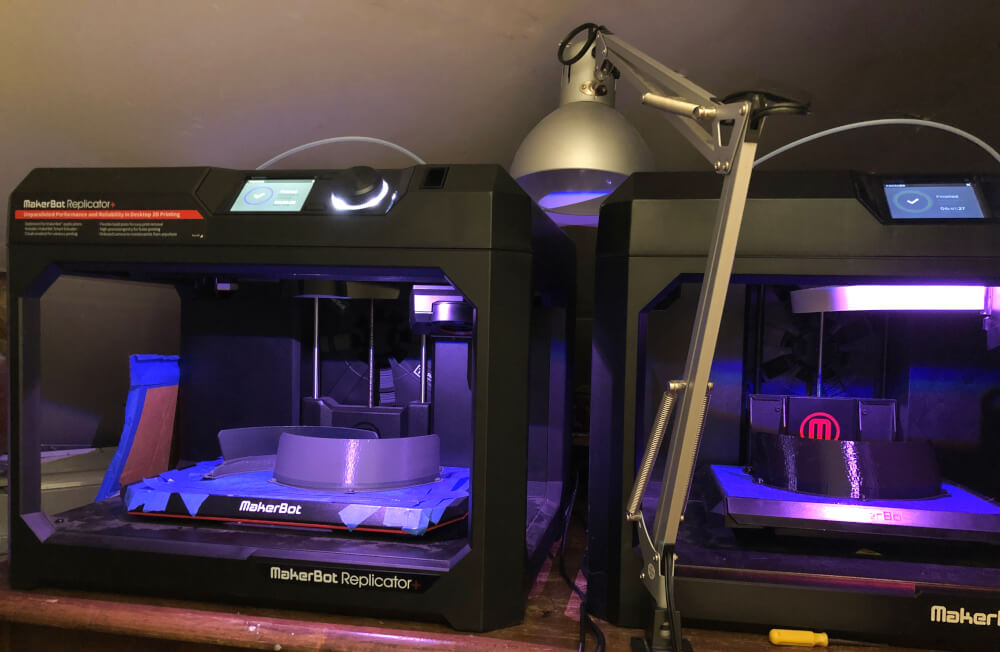

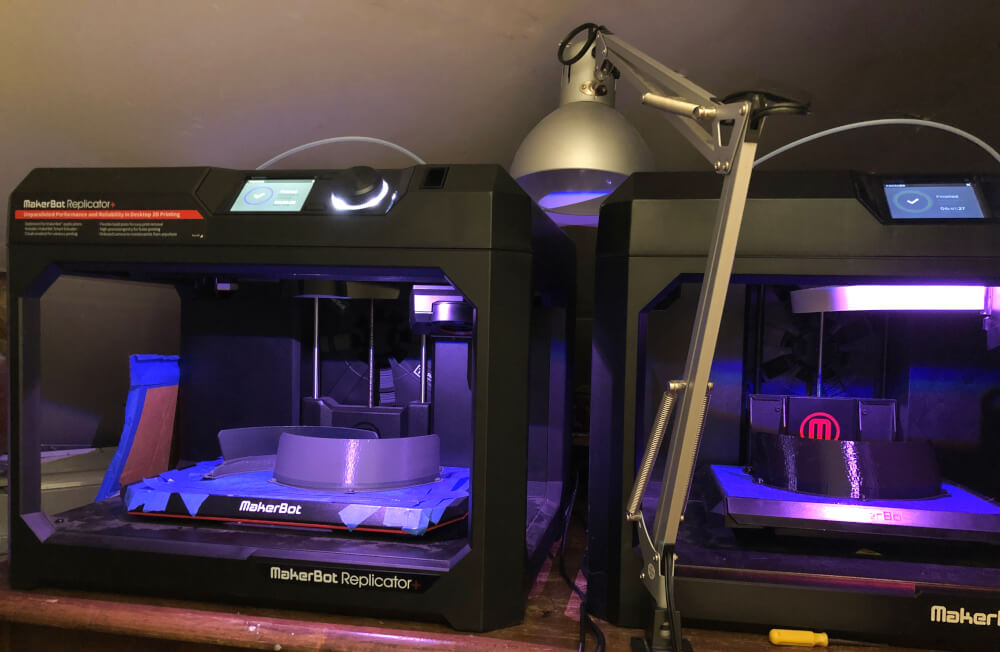

Chelsea Thompto, visiting professor for visual studies and foundations, is running two printers at home, while Norwood Viviano, associate professor of sculpture and foundations, is running one printer.

The project is an all-day, every day effort to create about 100 pieces. The faculty members are using the printers to create the head gear for the piece, and it takes upward of five hours for each one, they said.

The specifications for the face shields come from a file approved by the National Institutes for Health, Viviano said. The part used on the 3D printer is made of an environmentally friendly corn-based plastic. The rest of the piece involves a simple transparency with a three-hole punch and a rubber band.

While the transparency will have a shorter life span, Viviano said, "In theory the elements that fit right onto the head could have an infinite number of uses as long as they are disinfected."

The face shields will be shipped to Holland Home and other regional medical facilities, said Katie Branch, director of simulation.

“During COVID-19 the level of dedication and commitment across the university to the health care needs of our community has been remarkable," Branch said. "These efforts are reflective of Grand Valley’s continuous collaborative spirit and dedication to strong community partnerships.”

Thompto was inspired to approach VMA colleagues to undertake such a project after seeing discussions in professional networks about work done with 3D printers to create personal protective equipment. The first instincts were to create masks, Thompto said, but it became clear that face shields were more realistic for reproduction.

The response from VMA was enthusiastic.

"I was having a feeling that it would be great to give back in some way and I knew the university has that commitment," Thompto said. "I could donate the expertise I have, the department donates the equipment and materials, and we can support the community. It feels great to leverage the resources that were already available."

Viviano, who noted 3D printing has become "significantly faster and significantly less expensive" in just a few years, has long thought the process would become more mainstream; current circumstances have hastened that movement.

"I think the thing that has been interesting for me as an artist and as a human processing what is going on, is that 3D printing exploded when the need came on so dramatically," Viviano said. "This event synced up with an opportunity to dive into the technology for some people."

Subscribe

Sign up and receive the latest Grand Valley headlines delivered to your email inbox each morning.