School of Engineering Policies & Procedures

Access Cards

- The policies for student use of access cards in the Kennedy/Keller/Eberhard & 609 Watson Engineering Buildings are as follows:

- For safety purposes, all students utilizing an Engineering Building during any non-business hours (Daily after 5 p.m., plus Weekends and Holidays) are required to use the "buddy system" while in the rooms of any building. This means there must be a minimum of two (2) students within any occupied room within any School of Engineering building.

- If you are unsure if other engineering students will be in a building when you arrive, you may bring one guest with you. This guest must be over the age of 13 and be capable of following EMERGENCY PROCEDURES located directly adjacent to telephones in each lab of the Engineering Buildings. This will satisfy the "buddy system" requirement.

- YOU ARE NOT ALLOWED TO WORK IN AN ENGINEERING LAB ALONE. Should Pew Campus Security personnel find you in any engineering building alone, they have the authority to confiscate your access card and escort you from the building.

- The last group or individuals entering the building or a room will be held responsible for any damage or loss that occurs within that room or building.

- The roof of the Keller Engineering Building is off limits to all students unless escorted by faculty or supervisory staff. Violation of this rule will result in the revocation of your Engineering Building access card for the remainder of the current semester plus an additional semester.

- Unapproved entry into any space (i.e. locked store rooms, conference room, labs, faculty/staff offices, etc.) will result in revocation of your access card privileges for the remainder of the current semester.

- The following locations are classified as normal 24-hour-per-day spaces and can be accessed and occupied by all engineering students currently enrolled in engineering classes:

- Keller Engineering Laboratories East Entrance - all access cards will open

- Keller 202 Fluids Mezzanine Computer Lab - all access cards will open

- Keller 211 Design Bay Mezzanine Computer Lab - all access cards will open

- Keller Engineering Laboratories East Entrance - all access cards will open

- Kennedy/Keller Southwest Entrance – all access cards will open

- Kennedy North Entrance – all access cards will open

- Kennedy 244 Computer Lab – all access cards will open

- Kennedy 258 Computer Aided Design Lab – all access cards will open

- Kennedy 322 Computer Lab – all access cards will open

- Kennedy 358 Grad CS/CE Lab – all access cards will open

- Access to labs other than those mentioned in item 2 above will be by prearrangement with the appropriate School of Engineering faculty and lab supervisor.

- After hours access to School of Engineering facilities by students not enrolled in engineering or computer science classes on the Pew Campus and not guests of engineering students will be by prearrangement with the appropriate School of Engineering faculty and lab supervisor.

- Electrical power to individual laboratories will be on only when the appropriate building or lab is supervised.

- Only students who have been qualified on specific equipment may operate that equipment. Qualification policy and procedures are addressed separately.

Failure to follow the ABOVE policies & procedures will result in revocation of access privileges

Should you not return your access card when dropping from the School of Engineering or via graduation, PEW Campus Operations will place a lien on your financial student account. Should your access card be lost or stolen, it is your responsibility to immediately report it to Pew Campus Security and the School of Engineering.

If it is found that your card provided access to Engineering Facilities that resulted in a theft of tools or equipment, you will be personally held responsible for loss and damages. Your access card must be returned to either of the Laboratory Supervisors upon graduation or the student's departure from School of Engineering enrollment.

Working in the Labs

Whoever turns power on in a School of Engineering lab is thereby responsible for the safety of the engineering students working in that lab. Student safety responsibility can be verbally transferred between faculty and staff during normal business hours of 8 a.m. to 5 p.m.

The keyed lab power control switches are an integral part of the School’s safety program and are used provide an additional level of insurance of safety for students using any School of Engineering building.

The managerial responsibility of lab power is a shared decision between School of Engineering faculty and laboratory supervisors. Unless otherwise directed, Laboratory Supervisors will secure power to labs at approximately 5 p.m., Monday through Friday, during academic semesters.

Should faculty have the need to keep power on in labs beyond 5 p.m. daily, or on weekends, arrangements must be made with the appropriate building Laboratory Supervisor. Depending on the function of the lab and safety issues involved inside a lab, card access may, or may not, be granted to students during after hour times that power is left on in the lab. That decision should be made jointly by the faculty user and the building Lab Supervisor. Should the building Lab Supervisor have the student worker available, it is possible for power to be left on in labs during evening hours, with a supervisor present.

The two persons in each lab rule applies at all times, regardless of time of day, lab power on or off, building supervised or not.

Electrical & Computer Engineering Labs

ECE Laboratory Safety

- Respect the power of Electricity! Always check for voltage prior to connecting, disconnecting or touching your Circuit.

- Never work in a laboratory alone, make sure you have a partner who is able to use the Emergency Power Shutoff and call for help. (Phones are located in all rooms with emergency power shutoff)

- Know where the Emergency Power Shutoff is for the laboratory you are working in. (Note: Only Instructors or Laboratory Supervisors have the key to turn the power back on)

- Remember a shock hazard is always present when working with electrical or electronic circuits, make sure your work and equipment is grounded and in good operating condition.

- Obtain proper training before attempting to use any electronic equipment or tools.

- Before Operating Equipment check the Policy & Procedures for Shop Qualifications. On most equipment in the School of Engineering you must be qualified prior to its use.

- Use static straps to prevent electrostatic discharge (ESD). A small “snap” can destroy your chip or memory card.

- When Soldering, always solder using proper soldering procedures. Safety glasses MUST be worn. Use of the ventilation hood is required when soldering.

- Always follow the Policies & Procedures for students working in labs.

- If you don’t understand how something works or unable to get something to work always ask for assistance by a Laboratory Supervisor or Instructor.

Mechanical & PDM Labs

These guidelines address equipment and procedures that will mainly be used by those utilizing Mechanical and PDM laboratories.

The environment in which you are being taught within the Kennedy and Keller Building labs closely resembles that which is found in factories and other industrial facilities. Consequently, personal safety equipment and dress standards of what is found in industry will be enforced.

There is a risk of injury when wearing inappropriate clothing and footwear, such as shoes that do not cover the entire foot, and long legged baggy pants, long baggy shirt sleeves, certain styles of jewelry, and loose clothing or hair are strongly discouraged. Signs posted at laboratory doors may specifically prohibit these or additional personal hazard items.

- DO NOT run your machine or piece of equipment until you understand the operation of, been qualified to operate by School of Engineering personnel, and signed a verification of understanding for that specific piece of equipment.

- Safety glasses MUST be worn anytime you are within 10 ft. of flying particles. It doesn’t matter if the material is plastic, wood, or metal. Should you provide your own safety glasses, they must meet ANSI standard Z87.1, which includes having side shields.

- DO NOT operate any power or machine tool while under the influence of drugs, alcohol, or any medication.

- KEEP all power and machine tool guards in place and in working order. Loose objects can become flying projectiles.

- TAKE OUT all chuck keys and adjusting wrenches from power and machine tools before turning the power on.

- KEEP your work area clean. Cluttered areas and benches invite accidents.

- DO NOT wear gloves when operating power or machine tools. They are easily caught in moving parts. Take them off before you turn on a machine.

- WEAR only a canvas or leather type shoe that covers the ENTIRE foot.

- DO NOT use power tools in damp or wet locations.

- DO NOT force your power or machine cutting tool. It will do the job better and be safer at the rate for which it was designed.

- USE the correct tool. Don’t force a tool or attachment to do a job for which it was not designed.

- SECURE your work. Use clamps or a properly fastened vise to hold work when practical. It’s much safer than using your hand and frees both hands to operate the tool.

- PROTECT your hands. Always allow a spindle or blade to stop completely before you clear away chips or oil. USE a brush or chip scraper.

- DO NOT ever reach around a safeguard.

- DO NOT get trapped. Avoid placing your fingers, hands, arms, legs in power and machine tool pinch points.

- DO NOT overreach. Keep proper footing and balance at all times.

- USE your powers of observation when using any power or machine tool.

- ALWAYS feed your work into a blade or cutter against the direction of rotation of the blade or cutter only.

- ALWAYS inspect tools and blades for damage. Dull and damaged tools break easily and create more work. Keep tool overhangs short, i.e. long lever vs. short lever.

- NEVER look directly at a welding arc ray. Large amounts of ultraviolet light rays are produced and can cause eye pain and temporary blindness.

- NEVER leave a power or machine tool running unattended. If you step away even for a minute, TURN POWER OFF.

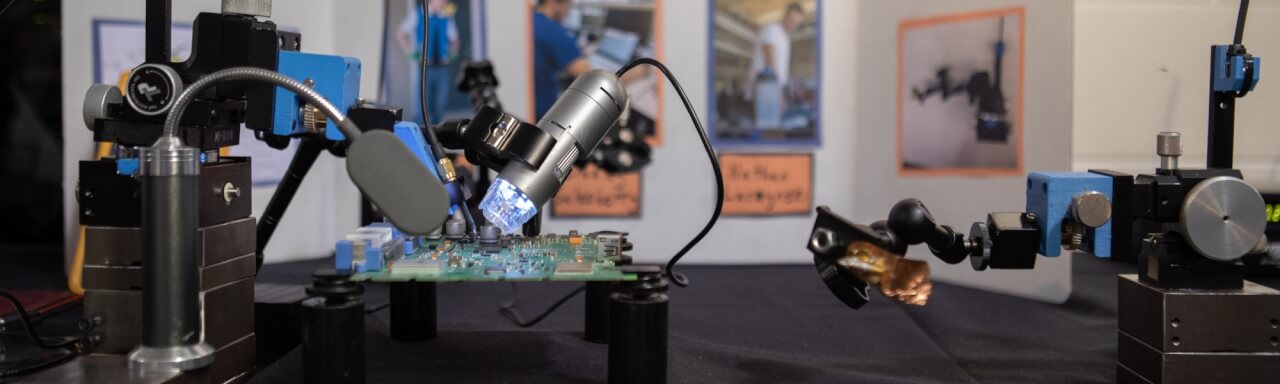

- ROBOTS in motion can be dangerous, especially during training, programming, and testing.

- RETURN tools to their proper place and in good working order. Inform the safety supervisor of any necessary replacement or repairs.

- SHOULD you become angry, rushed, or tired, STOP WORKING! Return to your job when you are better prepared to work safely.

- Always follow the Policies & Procedures for students working in Labs.

Qualifications

Students must be qualified to operate most equipment located within the School of Engineering laboratories. Qualification is required in order that students have knowledge of safety and operating procedures associated with particular processes, equipment, and machinery.

Qualifications are required for the below listed processes, equipment, and machinery.

- KEB Haas CNC High Torque

- KEN BenchMill. H.S. Haas

- KEB Wood Shop. Offered to students who have been selected for secondary admission to the School of Engineering.

- KEB Machine Shop Safety, procedures, saws and drills. Offered to students who have been selected for secondary admission to the School of Engineering.

- KEB machine shop manual mills. Offered to students who have been selected for secondary admission to the School of Engineering.

- KEB machine shop manual lathes. Offered to students who have been selected for secondary admission to the School of Engineering.

- KEB Welding and Plasma cutting machines. Offered to students who have been selected for secondary admission to the School of Engineering.

- KEB NC vertical machining center. Offered to students taking course EGR 367.

- KEB NC turning Center. Offered to students taking course EGR 367.

- CE Laboratory Safety Procedures. Required of all students using KEN|KEB ECE Labs and/or working with high and low voltage lab equipment.

- KEB 3D printer (rapid prototype printer) with Soluble Removal System Cleaning Station.

- EGR Lab Safety/Info Session

- KEN Through Hole Soldering. Offered in EGR214 to all students using ECE labs.

- KEN Surface Mount Soldering.

- KEN Electronics Assembly Lab

- KEN 242 laser engraver.

The qualifying student will sign and date a verification of understanding form as each step of the qualification process is completed. The qualifying student will either be given one business card sized qualification card or present a current qualification card that will be endorsed by the qualifying lab supervisor.

Students are to carry their qualification card on them at all times when operating School of Engineering equipment. Students may have to present the card whenever challenged for his/her qualification or when working in a SOE laboratory. The challenge can come from either faculty or staff of the School of Engineering.

The verification of understanding form will be maintained on file in the students’ records which are kept in the engineering office. (KEN136).

Qualification opportunities will be advertised in the form of a calendar with a heading that says “SCHOOL OF ENGINEERING QUALIFICATIONS SCHEDULE. The Schedule will be posted throughout KEN/KEB showing dates and times qualifications will be done. Once the schedule has expired for the semester, it is final.