PCEC News

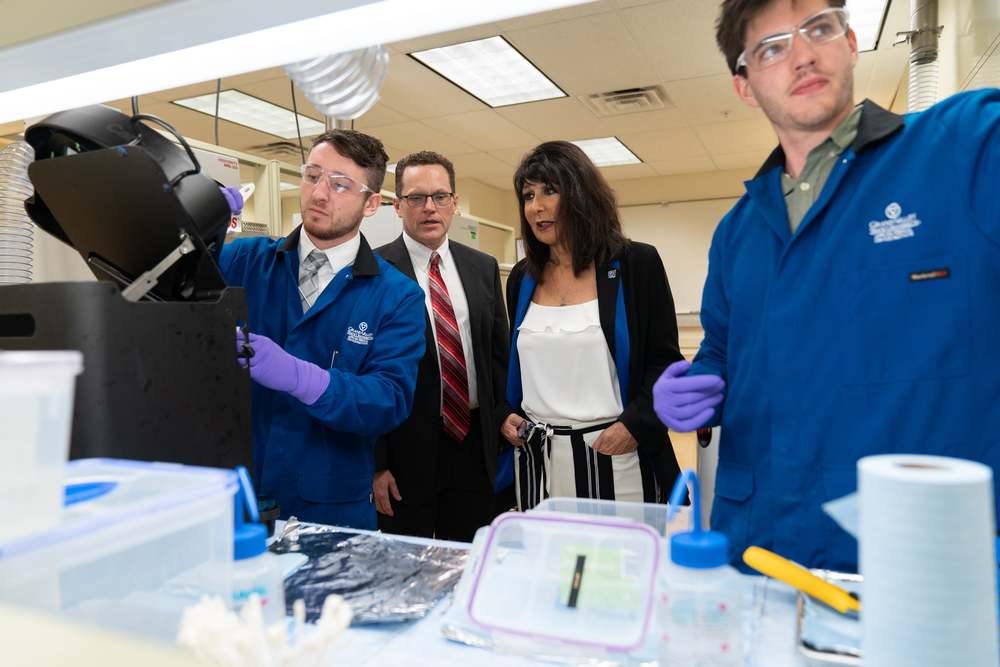

GVSU Engineering Students Integral to Carbon Production Partner Certification for aMDI and MediSurge

December 09, 2019

The applied Medical Device Institute (aMDI) within the Padnos College of Engineering & Computing at Grand Valley State University and industry collaborator, MediSurge, were recently certified as Carbon Production Partners (CPP). This certification made aMDI and MediSurge the 4th and 5th organizations in North America that were approved as medical device focused production partners for prototyping and manufacturing services with Carbon 3D’s liquid photopolymer additive manufacturing equipment.

GVSU’s aMDI became the first university-based organization to be included in the Carbon Production Network. Carbon 3D is a leading company in the expanding field of additive manufacturing for liquid photopolymer resins. The collaboration between aMDI and MediSurge has been made possible by support from the City of Grand Rapids’ Local Development Finance Authority (LDFA). Such a collaboration has provided a valuable community resource for local entrepreneurs and companies to accelerate their medical device design and development right here in Grand Rapids.

Team members from aMDI and MediSurge completed 140 to 200+ online training modules to learn the ins and outs of liquid photopolymer additive manufacturing and post processing with the Carbon 3D M2 printer. GVSU engineering co-op students, Breanna Andrews, Brianna Tramelli, Noah Keefer, and Rebecca Jacobs, as well as engineering graduate assistant, Aldo Fanelli, and GVSU biomedical sciences alumni and current aMDI Project Administrator and Lab Supervisor, Cody Rash, played crucial roles in the successful completion of the certification process. Test “coupons” were printed and post processed for key Carbon 3D resins including SIL 30, EPU 40, FPU 50, RPU 70, EPX 82, UMA 90, MPU 100, and CE 221. Carbon 3D technical experts inspected and reviewed the test coupons for print or processing defects and granted certification to aMDI and MediSurge in all these materials. The Carbon certification process has provided an excellent experiential learning opportunity for GVSU engineering students and developed skills sets for them in the liquid photopolymer additive manufacturing field.

After completion of the rigorous certification process to become part of the Carbon Production Network, both aMDI and MediSurge are ready to support clients with their 3D printing needs from prototyping to production. 3D printing in Carbon materials is available for university and public company projects on a fee-for-service basis. In addition to 3D printing, aMDI and MediSurge also provide engineering design and development services for entrepreneurs and companies. Please contact either John Hall, Principal Engineer at aMDI, at [email protected] or (616) 331-5751 or Rick Shorey, Senior Director R&D at MediSurge at [email protected] or (616) 292-5184 for more information. Engineering students who are interested in learning valuable liquid photopolymer additive manufacturing skills should also reach out to John or Rick.

Written by: John D. Hall, MS, Principal Engineer & Project Manager, applied Medical Device Institute