Experience Matters

You can filter your search by typing in an employer name, or selecting a major. This is a great way to see what possibilities are out there!

Campaign Intern

Emily

Major: Political Science

Tasks mainly consisted of house canvassing and talking to voters at their door about issues that my political candidate was concerned with. Other tasks included putting up yard signs and making phone calls for absentee voting and Get Out the Vote effort.

Yanfeng Co-op 3

Trevor

Major: Mechanical Engineering

Develope feasible designs for interior automotive components as well as manage high level assemblies (50+ components/part numbers).

3rd Co-op at GM

Alex

Major: Mechanical Engineering

I completed various activities regarding development of cam phasing technology. I also worked on completely a few test requests to support other product engineering activities.

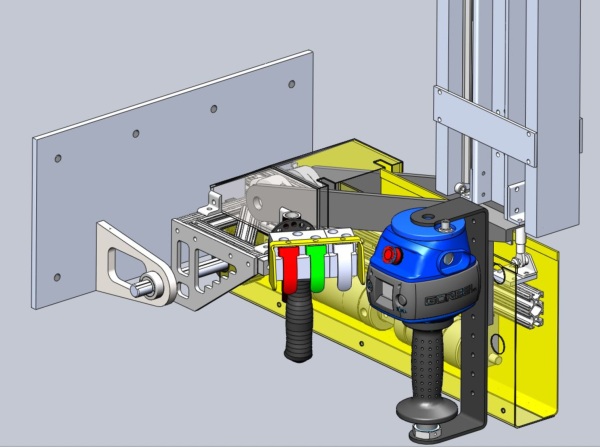

Mechanical Design at JR Automation

Preston

Major: Mechanical Engineering

I participated on the Mechanical Design team, helping support primary design engineers on a variety of projects. I participated in design checks, print detailing, and was able to help solve a multitude of complex problems with my own designs over the course of the semester.

Engineering in Deutschland

Andrew

Major: Interdisciplinary Engineering

My tasks and projects focused on supporting the product development team, specifically the prop shaft and dynamic damper engineering teams. I conducted benchmarking work on a new product that reduces noise and vibration and turns it into sound and comfort on new BMW vehicles. I also worked with the data in the form of hysteresis curves for tolerance development submitted to automotive companies. Daily tasks usually included doing applied math problems for decision-making big and small.

Magna Co-op III

Mitchell

Major: Mechanical Engineering

I will have participated in two innovation projects/meetings this semester. Innovation involved designing a prototype to be presented at an innovation meeting. I was able to use CAD to design the prototype part and 3D print or CNC machine the part to create the physical model. I also worked on various lighting and mirror testing tasks that were assigned by engineers within my department. I worked on several display/fixtures for outside mirrors to be shown at meetings and shows. Furthermore, I worked on a project that required part performance tests to be ran on the Ford F-150 outside mirror. Lastly, another co-op and I managed two 3D printers. This involved managing what parts were to be printed and when, printer maintenance, and managing the inventory.

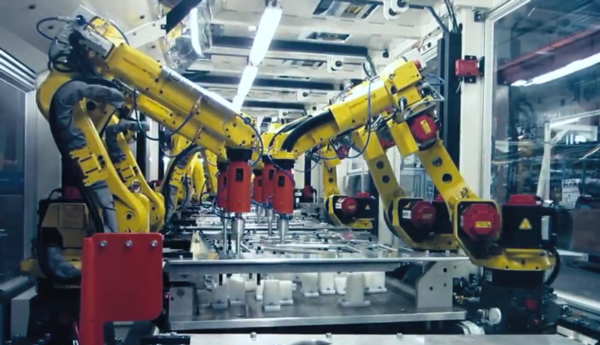

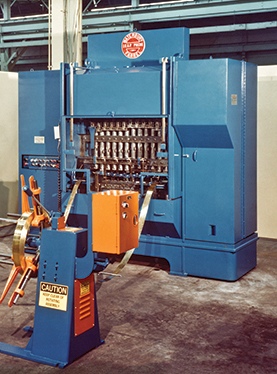

Third Rotation at JR Automation Technologies LLC

Jonathan

Major: Mechanical Engineering

Throughout my internship I detailed and checked prints of details and assemblies before they were released for fabrication and assembly. I was also tasked with designing small additions to existing cells that were already on the build floor. The parts I worked with varied from weldments, to sheet metal, to purchased components, and customer data.

Read More About Third Rotation at JR Automation Technologies LLC

APD Intern

Joseph

Major: Mechanical Engineering

Some of the tasks I do on a daily basis is operate the 3D printers, and manage the builds. I also build innovative prototypes for an innovation meeting each quarter (This is a lot of fun). I also benchmark outside mirrors, inside mirrors, and door handles on any vehicle. This is a great process that gets the interns familiar with what Magna Mirrors is all about. Working with other engineers on meaningful assignments when needed is also a task I accomplish. This could even mean projects or help on one of their own assignments.

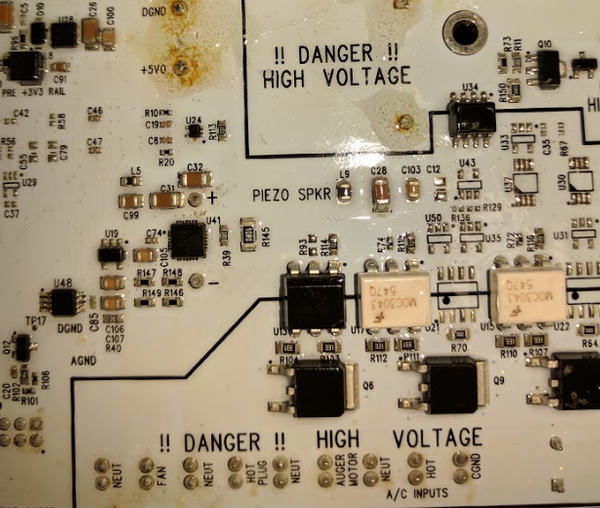

EBW Electronics Co-op III

Bryan

Major: Electrical Engineering

I did the PCB layout for a new product and put together all of the necessary design documentation. I also worked on creating thermal models of PCBs, so that the circuits hot spots can be predicted before prototypes are made. A couple other projects that I spent time on were working with an in-circuit programmer and helping with EMC testing.

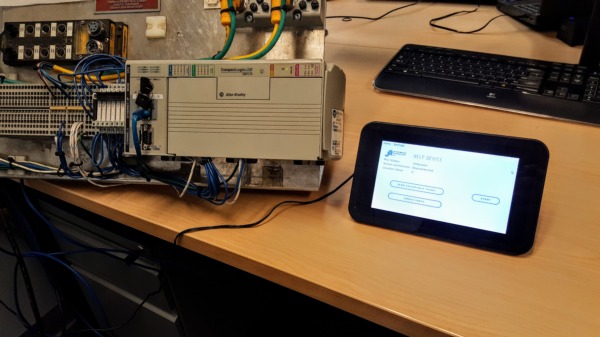

Controls Engineer - Automation

Joe

Major: Mechanical Engineering

Initially I was placed on a newly developed training cart. It was recently built and ready for programming/debug. The first month of my co-op was spent debugging wiring diagrams, electrical/pneumatic issues, and developing code with another co-op student. It was very beneficial for me to see the overall aspect of the controls engineering position. Having this broad understanding of how projects were ran, I was able to move into a larger project with confidence.

I was placed on a project, roughly a month into my co-op, with a more experienced controls engineer. I was initially given the task of developing a sensor list for the machine (500+ sensors in total), adding them into the electrical drawings, and submitting the order. Next, I was able to dive right into the programming portion of controls, setting up inputs and outputs. From there I developed and set up HMI screens for the 3 HMI's and 1 PC screen that were on the machine. This not only includes the initial layout/design but also linking each button to a PLC tag so when pressed, the correct signal was sent to the PLC. Lastly I created alarms and faults that would display on the HMI screens when an action wasn't performed correctly within the sequence. I was able to do just about everything an inexperienced controls engineer could do in his/her first few months of employment.

Herman Miller Options Engineering Co-op

Taylor

Major: Product Design and Manufacturing Engineering

I engineer a customer's special order that has deviations from the standard furniture product. I choose which products I want to engineer prioritized by order date. It starts with research on the standard products and the changes that were quoted. Then, I create the appropriate CAD parts and drawings that are needed for the order. The bill of materials would be altered by creating new parts, adding existing parts, and/or removing parts in order to match the order. I self check all of my work, then pass it onto another engineer to audit. My product is then signed off and sent to the next step towards manufacturing.

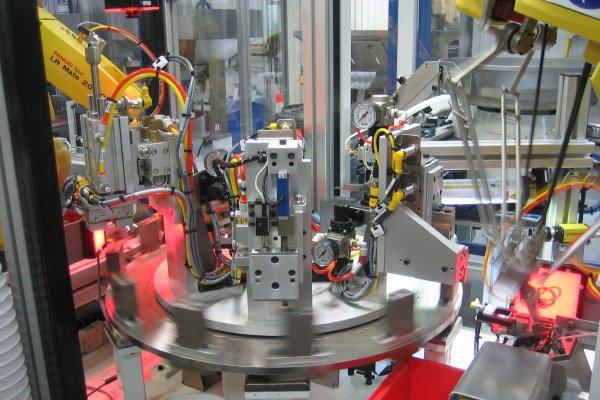

Koops Inc. Co-op

Alex

Major: Product Design and Manufacturing Engineering

As a member of the mechanical engineering team, I designed the custom automation machines produced by Koops. Some of this work involved making modifications to existing machinery, while other work was designing completely new machines. During the designing phase, I was involved in design reviews with customers and collaboration with other designers.

MotorGuide Electrical Engineering Co-op

John

Major: Electrical Engineering

I validated product changes throughout the semester. From component level analysis to software changes, I made sure the final assembly worked properly as optimizations were made.

Herman Miller - Manufacturing Engineering

Colin

Major: Product Design and Manufacturing Engineering

I spent a lot of time developing a gantry-mounted lift assist device that operators could use to easily pick up heavy counterweights with vacuum cups and install them into units.

I also had the chance to develop fixtures and enhance capabilities to assist operators in the manufacturing of new product.

I worked on adding additional features and systems to an automated cell.

Primarily, my projects were for safety or ergonomic related improvements. I would collaborate with internal and external toolmakers, mechanics, managers, and engineers to assist me in my project goals.

Co-op III

Ethan

Major: Mechanical Engineering

I worked with the systems engineering department to design and develop conveyor systems. This involved working with the customer to ensure everything desired was accounted for, calculating loads, providing drawings, and determining solutions.

EGR Co-Op III

Ryan

Major: Product Design and Manufacturing Engineering

This is my third rotation of co-op with Hydro-Chem Systems, each having more responsibilities than the previous. Daily tasks included created sales and production drawings to relay information regarding installation and manufacturing. Projects included product redesign and process improvement.

Computer Engineering Co-op at JR Automation

Ethan

Major: Computer Engineering

I've primarily worked on programming projects in C# and C++ for industrial robotics applications.

The majority of my time was on three projects:

In the first, I worked to create an embedded device to act as an internet gateway for diagnostics of machines.

In the second, I spent time developing a library on which much of the department's future projects will be based.

Finally, I spent time working on a system for flashing data to a particular microcontroller when triggered by a PLC.

Hard Work Pays

Josiah

Major: Electrical Engineering

Sadly the project that I worked on this semester is confidential. I can only say that during this semester I worked with AC Phase control using microcontrollers, wiring harnesses and signal control. This project was one of the most difficult that I have ever worked on and I was lucky to learn so much!

Co-op 3

Allison

Major: Computer Engineering

I continued some work on a prototype that I designed in my second co-op. The prototype is a stepper motor controller with universal software made backward compatible with a current product in development. The application is an irrigation pump device that receives commands and runs the motor accordingly. Sourcing issues arose with the original hardware chosen for the project, so I was asked to find a different stepper driver and microcontroller, and move my software onto the new hardware. This also was an opportunity for me to refactor my software, so I implemented a more versatile communication protocol. Flow rate tests confirmed that my prototype works effectively. I also designed and wrote software for some test boxes that simulate control devices used with another product in development. These test boxes had boards that were made, but were not programmed yet, so I took initiative to complete them and verify that they worked with the product.

Engineering Co-op

Andrew

Major: Mechanical Engineering

Tool design and metal stamping simulations. Trip to China to document engineering process abroad.

Part of the team at DornerWorks

Nicholas

Major: Computer Engineering

I worked on making a virtualization software compliant to an aerospace specification for use on satellites. I programmed in C in an ARM environment.

Hands On

Michael

Major: Computer Engineering

My tasks involved validating a new product line of Limelight.

Women's Center Internship

Justice

Major: Communications

I was brought onto their team as the 15th Year Anniversary Lead Intern. I was in charge of planning their fall celebration event during Grand Valley's Homecoming week. I was in charge of contacting multiple venues and choosing the one that best fit the vision of the center for the homecoming event. I was in charge of marketing the event, booking all the food and beverages for the event.

third co-op rotation at Dornerworks

Aaron

Major: Electrical Engineering

I tuned a PID control loop for an embedded system. I documented the progress that I made. I changed a Python GUI for a customer.

Making Machines Work

Benjamin

Major: Mechanical Engineering

I performed debugging adjustments to automated machines to bring the quality of the part up to what the customer expected. I also assisted with PLC programming, prototyping for the sales team, and mechanical design.

All opinions, conclusions or recommendations expressed are those of the author(s) and do not necessarily reflect the views of GVSU.